The importance of heat treatment

The effects on the material’s internal condition

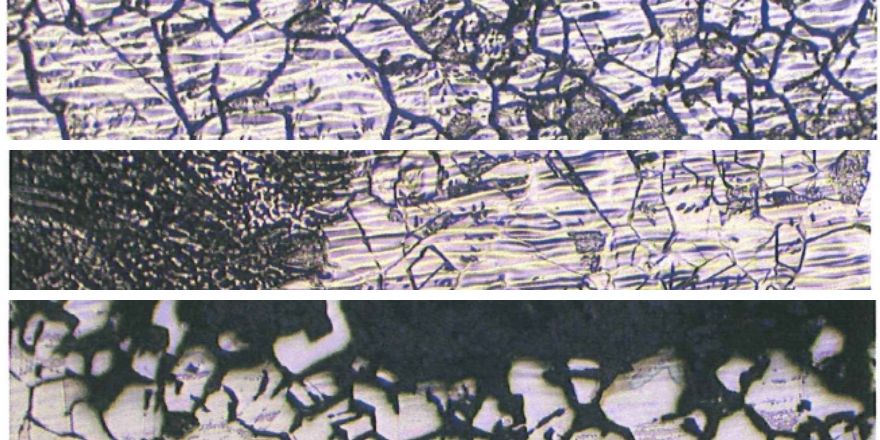

When casting or forging metal parts, several factors will influence the final properties of the material. These processes have an effect on the material’s internal condition, e.g., the shape and dimension of the grain structure, the distribution of the alloying elements and the presence of unwanted chemical reactions.

An essential step in the production of good materials is the importance heat treatment process. During the importance of the heat treatment, the material is heated up in a furnace at a pre-defined temperature for a prescribed time, after which it is cooled down in a prescribed way. There are many materials, and just as many heat treatment processes. Along with the chemical elements that the material contains (such as C, Mn, Cr and Ni), the heat treatment will determine the strength of the material and its chemical behaviour.

Common heat treatment processes

- Normalising (+N) carbon steel (e.g., G20Mn5): the material is heated to 925°C for two hours and then air cooled.

- Quenching and tempering (+QT) of low alloy steel (e.g., G42CrMo4): the material is heated to 925°C for two hours, then quickly cooled in water or oil. The result is a very hard and brittle material. After quenching, the material is softened by a tempering process at +/- 600°C.

- Solution annealing and quenching (+AT) for stainless steel (e.g., GX5CrNi19-10). The material is heated to 1,100°C for two hours, after which it is quickly cooled in water.