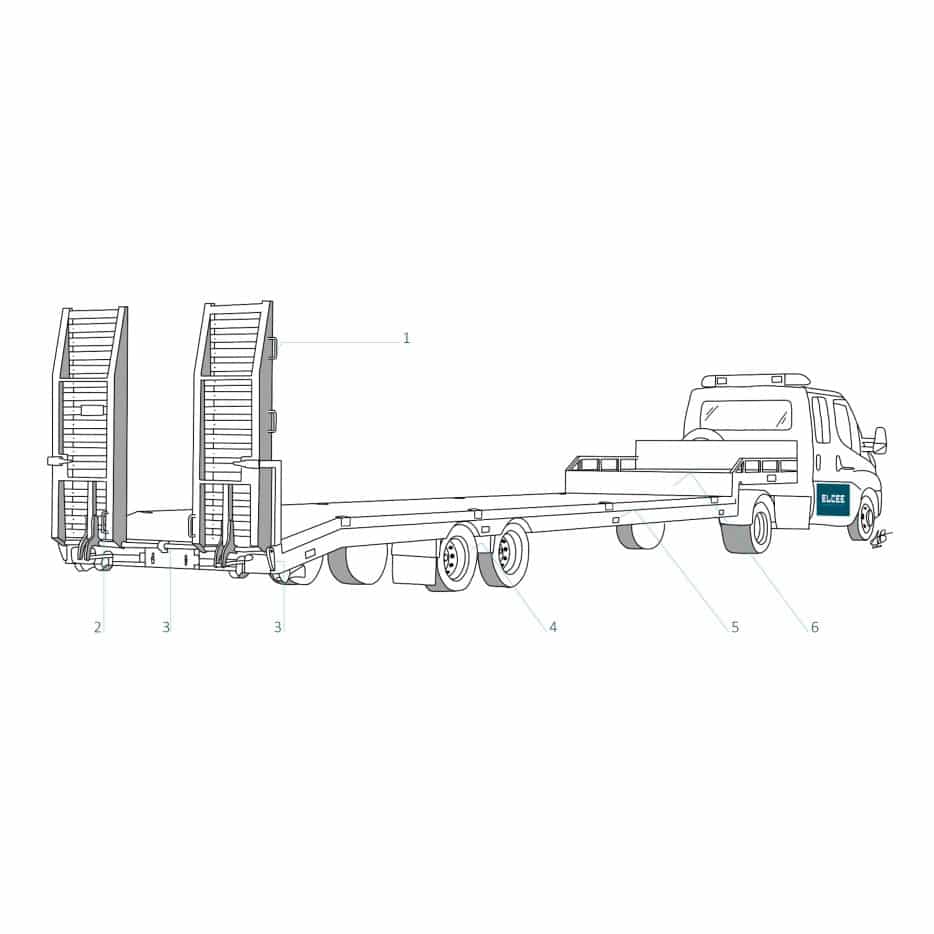

Typical ELCEE components in a trailer

transport industry

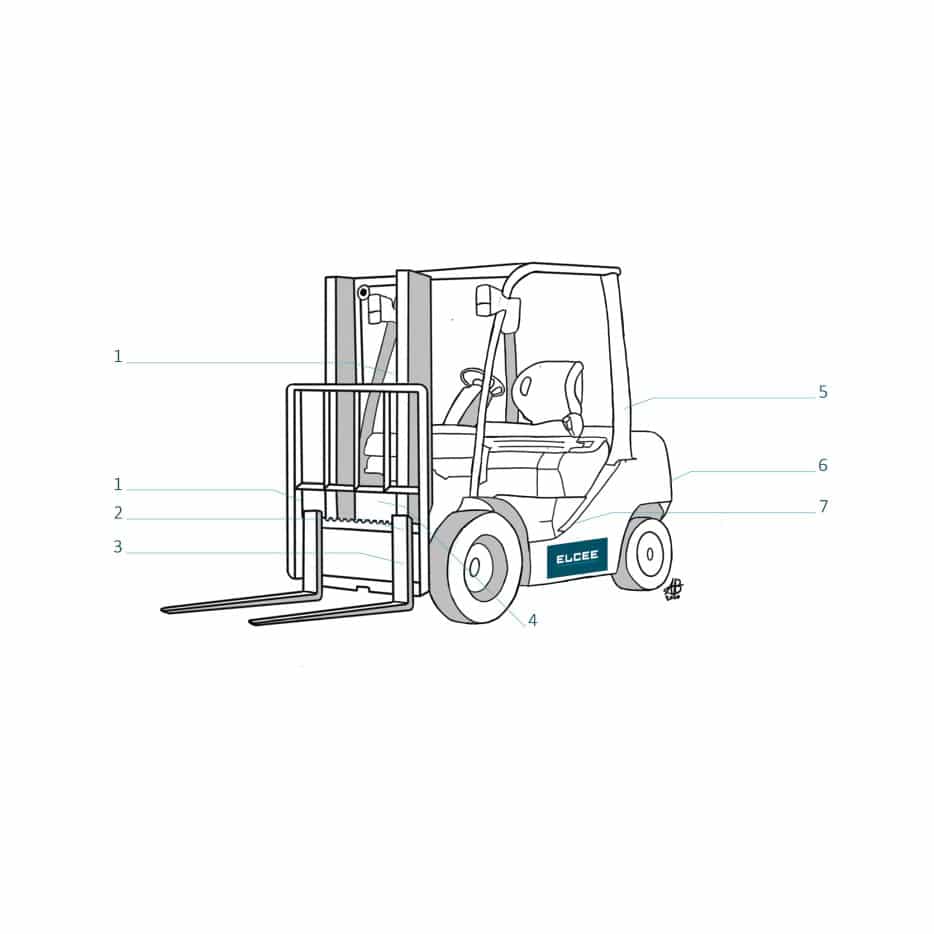

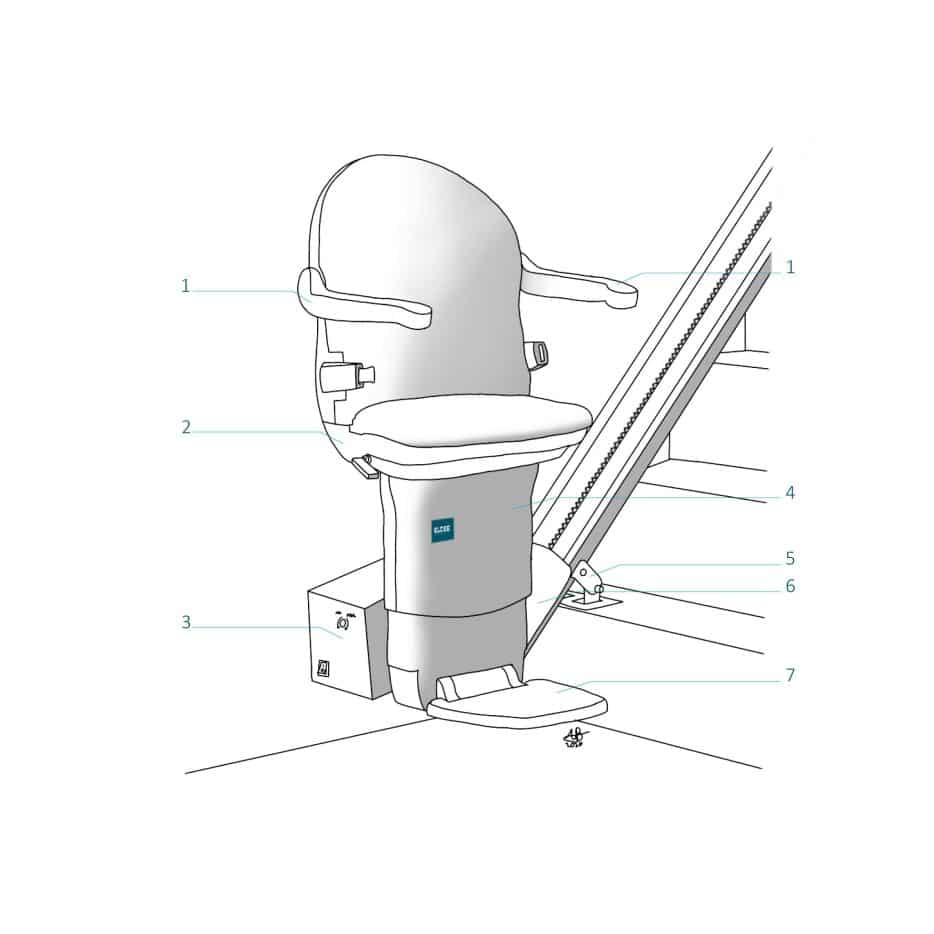

TYPICAL ELCEE COMPONENT LOCATIONS

Trailer

- (Suspension) brackets

- Steering parts (front)

- Lifting points

- Steering parts (back)

- Door hinges

- Ram rolls

- Locking blocks

- Mounting brackets

TYPICAL TECHNOLOGIES

- Investment casting (water glass process) Shell moulding

- Sand casting

- Closed die forging

- Assemblies

TYPICAL MATERIALS

- Steel

- Stainless steel

At ELCEE, we utilize a diverse range of typical technologies to manufacture high-quality industrial components tailored to meet the specific needs of our clients. One of our key processes is Metal Injection Moulding (MIM), which allows for the production of complex geometries with excellent dimensional accuracy and surface finish. This method is particularly effective for intricate parts that require high strength and durability.

We also employ high-pressure die casting, a process ideal for producing aluminum components with outstanding precision and surface quality, making it suitable for high-volume production runs. Additionally, our sintering technology enables us to create solid parts from powdered materials, which is especially beneficial for producing components with unique characteristics and properties.

Investment casting, particularly using the silica sol process, allows for the creation of highly detailed and high-strength parts, suitable for demanding applications in industries such as aerospace and automotive. Moreover, closed die forging is employed to enhance the mechanical properties of metals through deformation, resulting in components that are both robust and reliable.

In terms of materials, we primarily work with steel, stainless steel, and aluminum, each selected for its unique properties. Steel and stainless steel offer exceptional strength and corrosion resistance, while aluminum provides a lightweight alternative without compromising performance. By leveraging these technologies and materials, ELCEE ensures that we deliver superior quality components that meet the rigorous demands of various industries.

Highlights Elcee components in applications

Our qualities

Know how

Thanks to 100 years of experience, we are proud to have an abundance of knowledge and expertise

Cost engineering

Transform welded assemblies into cost-efficient castings and forgings

Quality

Fully-equipped quality and material labs in Europe and Asia to perform in-house tests

Production

Over 150 qualified production locations around the globe

Local hero

Multiple offices worldwide: ELCEE is your local supplier in a global world

Supply chain

Organising the supply chain from production up to your production line