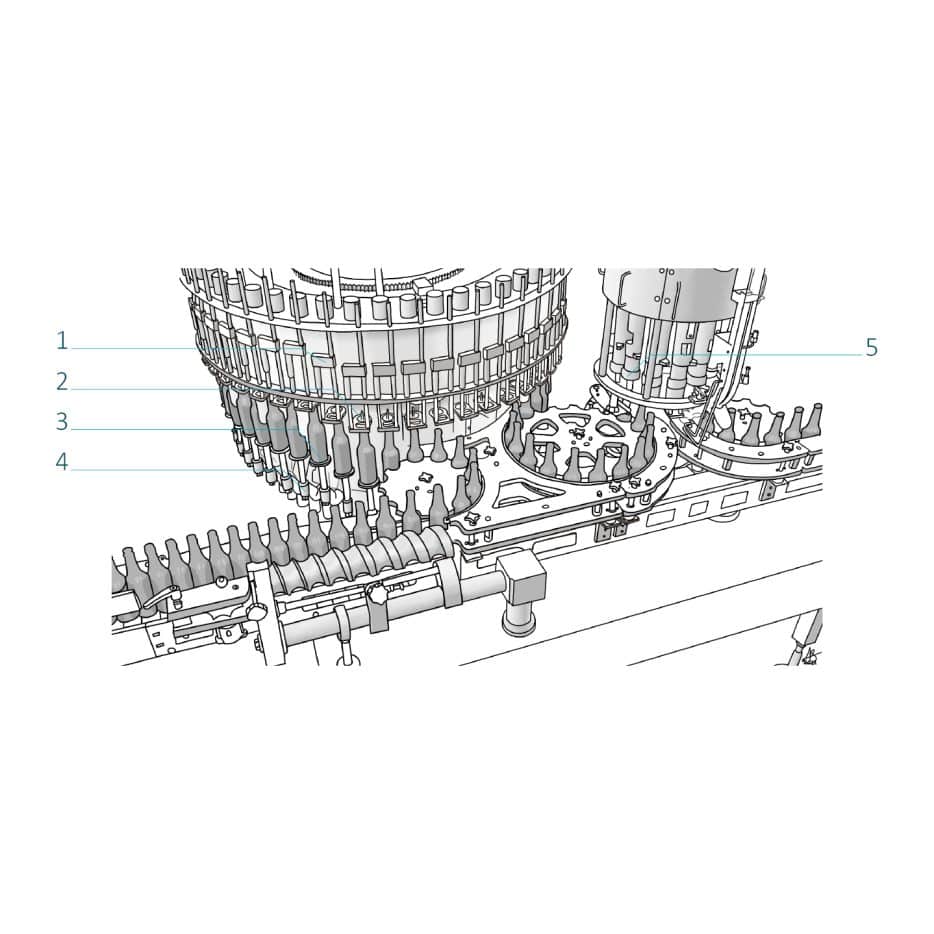

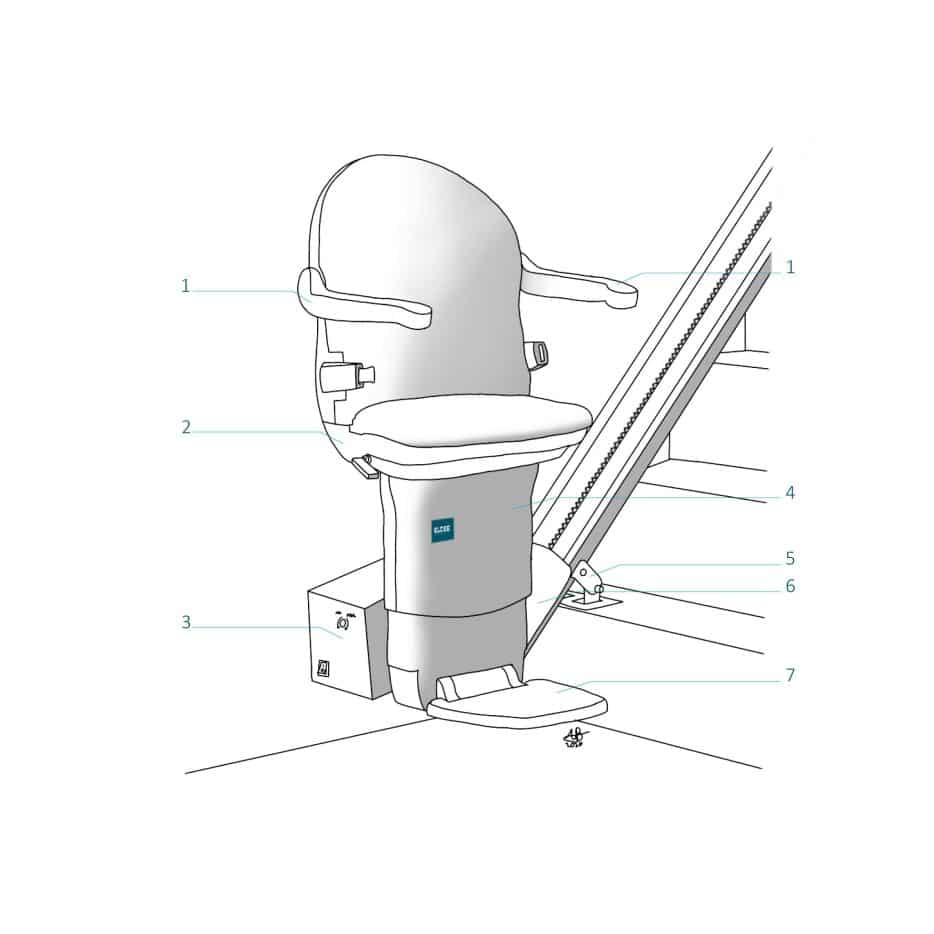

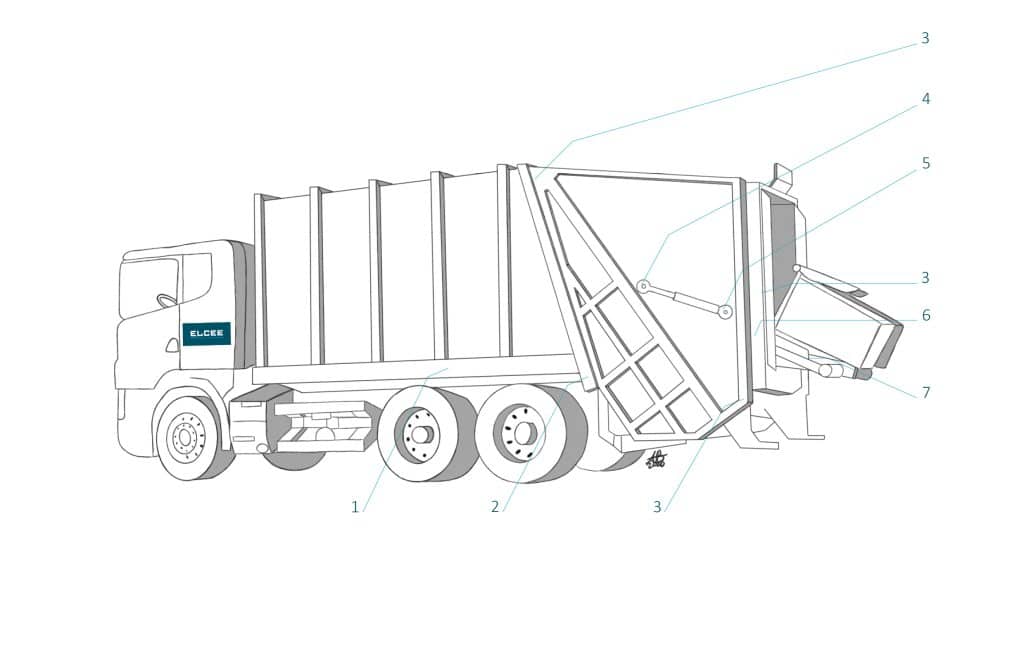

Typical ELCEE components in a garbage truck

Equipment manufacturing

TYPICAL ELCEE COMPONENT LOCATIONS

Garbage truck

- Brackets

- Locking points

- Hinge(s)

- Cylinder eye

- Cylinder support

- Container support

- Frame connections

Typical Technologies in Garbage Truck Manufacturing

Garbage trucks are vital for waste management and play a crucial role in keeping urban environments clean. The manufacturing of garbage trucks involves various advanced technologies and materials that ensure durability, efficiency, and reliability. Below are the typical technologies and materials commonly used in the production of garbage trucks.

Typical Technologies

- Investment Casting (Water Glass Process):

- The water glass process is utilized to create complex components for garbage trucks, such as brackets, housings, and other parts that require high precision and durability. This method produces high-quality parts with excellent surface finishes, making it ideal for components that must withstand heavy loads and harsh conditions.

- Investment Casting (Silica Sol Process):

- Similar to the water glass process, the silica sol process enables the production of intricate and detailed components. This technique is particularly effective for manufacturing parts that require tight tolerances and superior mechanical properties, such as pump housings and valve bodies used in hydraulic systems of garbage trucks.

- Shell Moulding:

- Shell moulding is employed to create robust components with complex shapes and fine surface finishes. This technology is advantageous for producing parts such as structural brackets and engine components, which are essential for the overall functionality and stability of garbage trucks.

- Closed Die Forging:

- Closed die forging is used to manufacture high-strength components that can endure significant stress and wear. This process is ideal for producing parts such as axles, gears, and other critical structural elements that require enhanced mechanical properties and durability in demanding environments.

- Assemblies:

- The assembly of various components is a critical aspect of garbage truck manufacturing. This process involves integrating parts such as the chassis, hydraulic systems, and waste containers into a cohesive unit. Efficient assembly techniques ensure that all components fit together accurately and function seamlessly, contributing to the truck’s overall reliability and performance.

Typical Materials

- Steel:

- Steel is the primary material used in the construction of garbage trucks due to its strength, durability, and cost-effectiveness. It is commonly used for structural components, frames, and chassis that must withstand the rigors of daily operation and heavy loads.

- Stainless Steel:

- Stainless steel is utilized in areas where corrosion resistance is essential, such as in the construction of waste containers and components exposed to harsh environmental conditions. Its durability and hygiene properties make it suitable for applications within the waste management sector, ensuring that components maintain their integrity over time.

Highlights Elcee components in applications

Our qualities

Know how

Thanks to 100 years of experience, we are proud to have an abundance of knowledge and expertise

Cost engineering

Transform welded assemblies into cost-efficient castings and forgings

Quality

Fully-equipped quality and material labs in Europe and Asia to perform in-house tests

Production

Over 150 qualified production locations around the globe

Local hero

Multiple offices worldwide: ELCEE is your local supplier in a global world

Supply chain

Organising the supply chain from production up to your production line