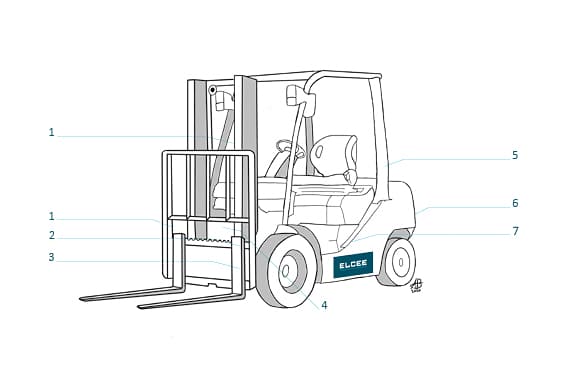

Typical ELCEE components in a forklift

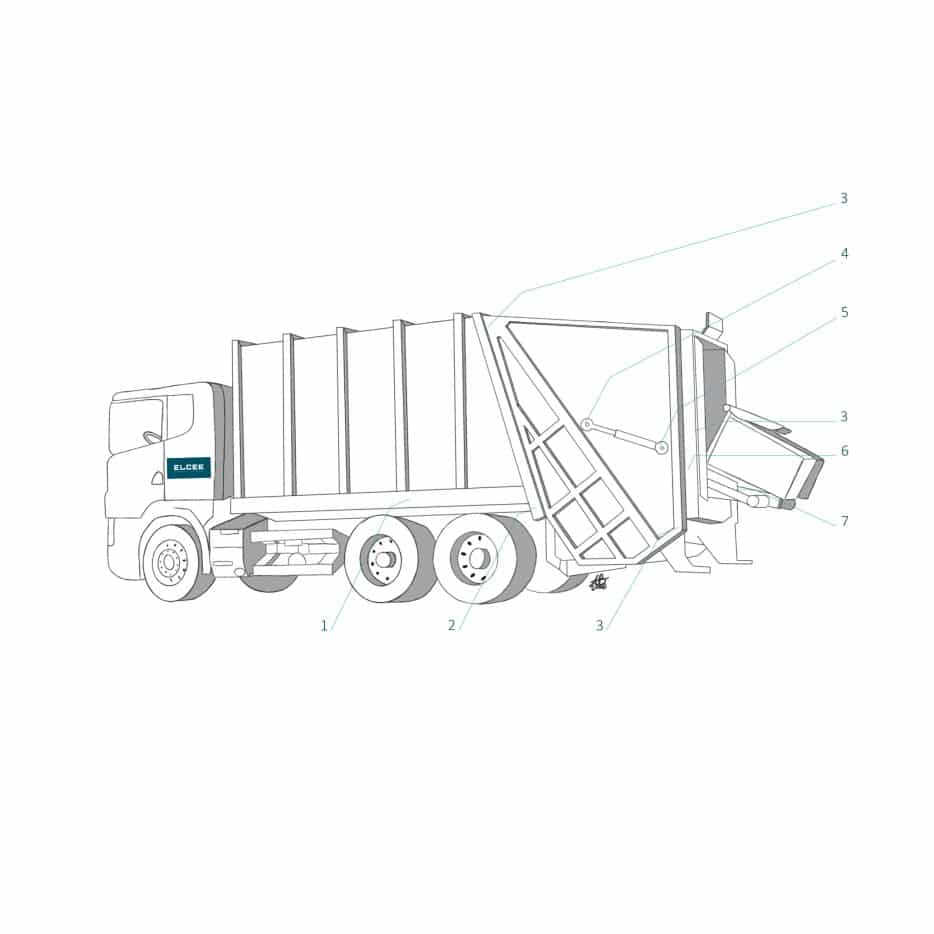

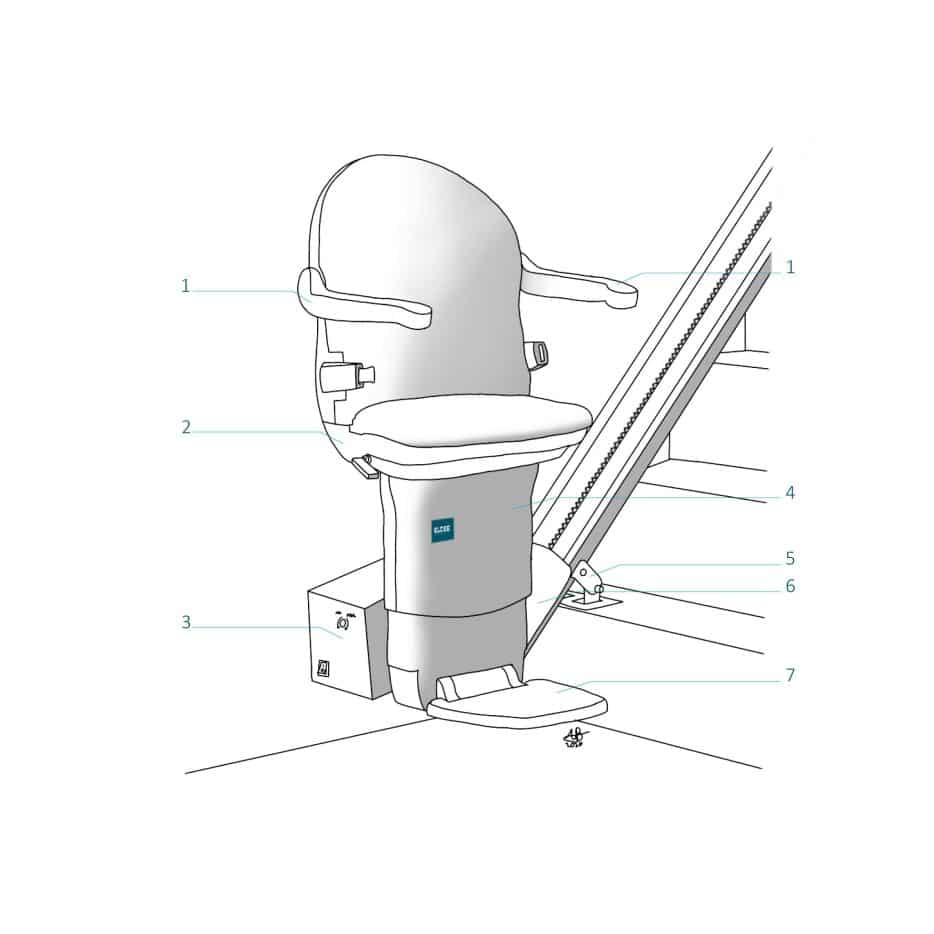

Equipment manufacturing

TYPICAL ELCEE COMPONENT LOCATIONS

Forklift

- Hinge mounting point

- Cylinder mountings

- Crossmember position

- Bushing point

- Bar

- Counterweight

- Steering & suspension components

Typical Technologies in Forklift Manufacturing

Forklifts are essential pieces of equipment in warehouses and manufacturing environments, designed for lifting and transporting heavy loads. The manufacturing of forklifts involves various technologies that ensure high performance, durability, and safety. Below are some typical technologies and materials used in forklift production:

Typical Technologies

- Investment Casting (Water Glass Process):

- This method is used to create complex components with precise dimensions and excellent surface finishes. The water glass process provides the strength and durability needed for critical parts such as engine blocks and gear housings, ensuring reliable operation in demanding environments.

- Shell Moulding:

- Shell moulding is employed to produce parts with intricate shapes and high dimensional accuracy. This technology is beneficial for manufacturing components like brackets and housings that require both strength and a smooth surface finish. The shell moulding process allows for efficient production of medium to high volumes of parts.

- Sand Casting:

- Sand casting is a versatile and widely used method for producing larger components. It allows for the creation of various shapes and sizes, making it ideal for parts like frames and support structures in forklifts. This process is cost-effective for low to medium production volumes and accommodates a wide range of metal alloys.

- Closed Die Forging:

- Closed die forging is utilized to produce strong and durable components that can withstand heavy loads and stresses. This technology is particularly useful for manufacturing high-strength parts such as axle shafts and other critical structural elements of forklifts. The forging process enhances the material’s mechanical properties through controlled deformation.

- Assemblies:

- Forklifts are comprised of multiple assembled components, including the chassis, mast, and lift mechanisms. Efficient assembly processes are crucial to ensure that all parts fit together correctly and operate seamlessly, contributing to the overall performance and safety of the forklift.

Typical Materials

- Steel:

- Steel is a primary material used in forklift construction due to its high strength, durability, and ability to withstand heavy loads. Different grades of steel may be used depending on the specific requirements of each component, ensuring that the forklift can perform effectively in various applications.

- Iron:

- Iron is also commonly used, particularly in cast components that require excellent wear resistance and toughness. Cast iron parts, such as frames and counterweights, contribute to the overall stability and reliability of the forklift.

By leveraging these technologies and materials, manufacturers can produce forklifts that meet the rigorous demands of industrial environments while ensuring safety, efficiency, and longevity. If you would like to learn more about any specific technology or material in forklift manufacturing

Highlights Elcee components in applications

Our qualities

Know how

Thanks to 100 years of experience, we are proud to have an abundance of knowledge and expertise

Cost engineering

Transform welded assemblies into cost-efficient castings and forgings

Quality

Fully-equipped quality and material labs in Europe and Asia to perform in-house tests

Production

Over 150 qualified production locations around the globe

Local hero

Multiple offices worldwide: ELCEE is your local supplier in a global world

Supply chain

Organising the supply chain from production up to your production line