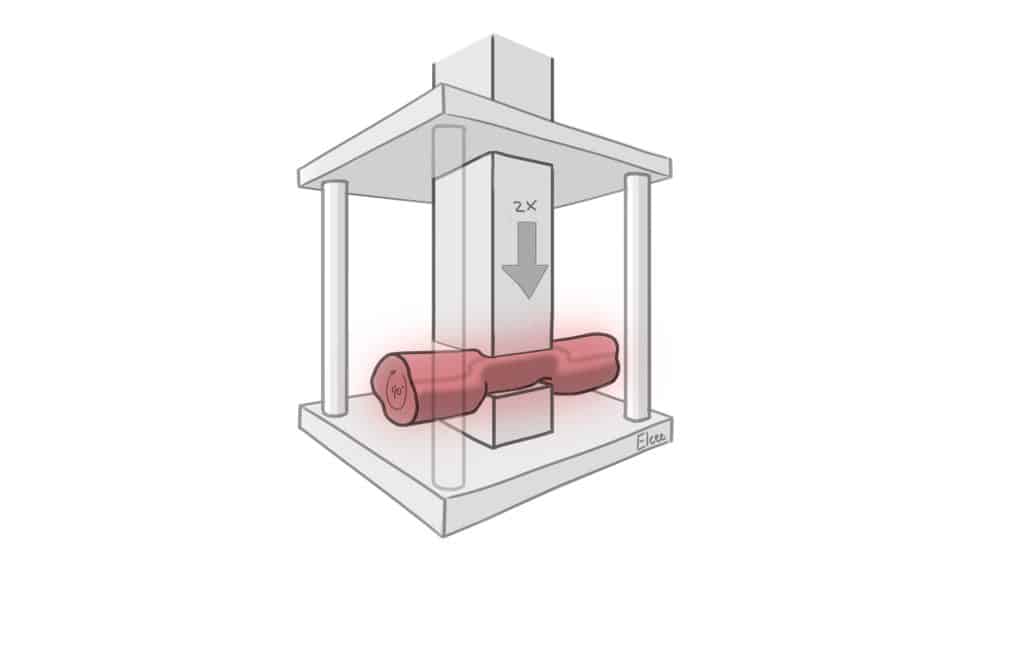

Open die forging

Open die forging is the best choice when large components of the material, with high exacting internal conditions (homogeneity), are required.

Open die forging is the best choice when large components of the material, with high exacting internal conditions (homogeneity), are required.

Manufacturing in the process that excels in producing large components where material integrity and internal consistency are paramount. This technique involves shaping metal by applying compressive forces using flat or contoured dies, which allows for greater flexibility in the design and dimensions of the final product. Particularly suited for applications requiring high levels of homogeneity, as it promotes uniform grain structure and enhances the mechanical properties of the material.

One of the primary advantages is its ability to accommodate large workpieces. This makes it an ideal choice for industries such as aerospace, oil and gas, and heavy machinery, where robust components are essential for the performance and safety of equipment. The process can produce parts of varying sizes and shapes, from simple blocks to complex geometries, while maintaining tight tolerances and high structural integrity.

The forging process also allows for significant deformation of the material, which aligns the grain structure and improves its strength and toughness. This is particularly beneficial in applications where components must withstand extreme conditions, such as high temperatures, pressure, and mechanical stress. Open die forging ensures that the final product exhibits enhanced fatigue resistance and durability, making it suitable for critical applications.

Moreover, it is highly adaptable, allowing for the handling of various materials, including steel, stainless steel, and other alloys. This versatility enables manufacturers to tailor components to the specific requirements of their projects. Additionally, the process can be combined with other methods, such as machining and heat treatment, to achieve desired characteristics and finishes.

At ELCEE, our expertise ensures that we can meet the diverse needs of our clients by providing high-quality, custom-engineered components. Our skilled technicians work closely with clients to understand their specifications and deliver solutions that exceed expectations. You gain access to a reliable manufacturing process that prioritizes both performance and quality, making it an excellent choice for your most demanding applications. Contact us today to learn more about how we can benefit your projects!

Benefits

- Small quantities

- Large parts

- No/low investment costs

- Long/big items can be forged

- Homogeneous material

- High strength

Possible alloys

- Alloy steel

- Steel

- Tool steel

- Stainless steel and duplex grades (such as 304 (L) or 316 (L)

- Aluminium alloys

- Bronze alloys

- Copper alloys

Technical specifications

- Weight: from 2 kg to hundreds of kilograms

- Wide tolerances

- Maximum dimensions: several meters

Finishing options

- Electrolytic zinc plating

- Hot-dip galvanising

- Blasting

- Primer, wet painting and powder coating