Gravity die casting (low pressure die casting)

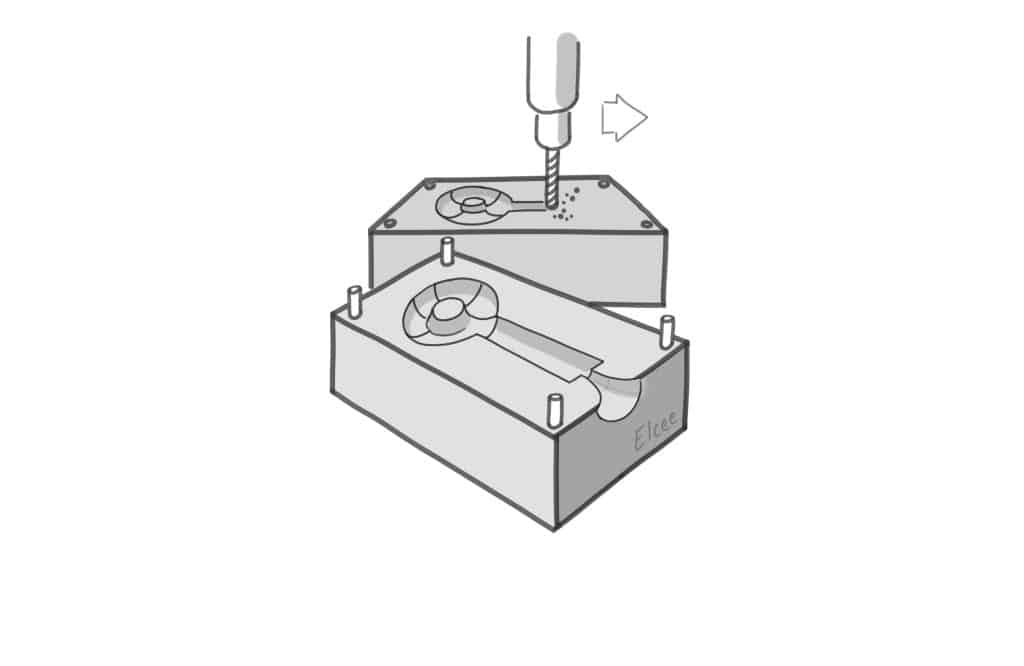

Complex internal cavities can be produced at the following ways.

Complex internal cavities can be produced at the following ways.

Benefits

- More possibilities compared with sand casting

- Consistent dimensional accuracy

- Possibility to insert metal parts in the casting (such as bolts, pipes etc.)

- Highly suitable for finishing operations

Possible alloys

- Aluminium alloys

- Magnesium alloys

- Copper alloys

Technical specifications

- The commonly used casting tolerance table for linear dimensions is CT8 according to ISO 8062 (wall thicknesses CT9)

- Weight: 30 grams to 80 kg

- Casting surface roughness: ± Ra 6.3 μm

- Maximum dimensions: 1000 mm

- Casting wall thickness: ≥ 3 mm. Wall thickness should be distributed as evenly as possible

- The geometric tolerances that are required for the function should be specified in the drawing

- The minimum draft angle depends on the height of the wall or rib. The higher it is, the smaller the required minimum draft angle. Minimum draft angle from 1°, starting from 2° – 3°

- The position of the ejection pins must be discussed with the customer

Finishing options

- Technically anodising, but not decorative (it turns a mottled matt black)

- Blasting

- Vibra-polishing

- Primer, wet painting and powder coating