The difference between multi- & single-start threads

What relationship do “thread” and a “spindle nut” have to each other? And what is the difference between a single- and multi-start thread?

Threaded spindles convert a rotational movement into a linear one. They consist of a cylindrical round bar on which a simple thread (transmission) is placed. The threaded spindles have the trapezoidal thread form of a dryspin® geometry designed by igus®.

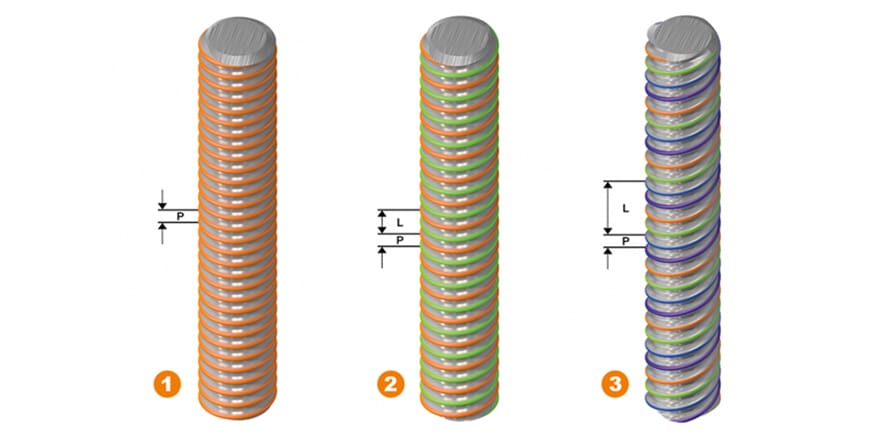

L = LEAD = Linear stroke in mm per one screw rotation

P = PITCH = Distance from thread to next thread

Single and multiple threads

- Single threads consist of a single thread (single start, number 1 in the diagram). The distance between the flanks, indicated by PITCH, is also the linear LEAD (L) in millimetres per revolution of the spindle nut.

- Multiple threads (number 2 in the diagram) have an additional thread, which allows the double LEAD to be achieved with one revolution of the spindle nut (LEAD= 2 x PITCH). The beginning of the thread is shifted by 180°, so that they are opposite to each other.

- 4-start thread spindles (number 3 in the diagram) have 4 thread starting points (orange, green, purple and light blue). For the linear LEAD the same calculation applies as for the other examples. The linear displacement (LEAD) is four times the distance between the flanks (PITCH). The start of each thread is at a position of 90° to each other.

A multiple thread is visually obvious. A multiple thread can be recognised visually, by looking at the front of the screws.

Single thread start

The start of the threaded spindles can be seen from above. The flank distance (PITCH) of the thread is equal to the thread starting length (LEAD).

Multiple start of the thread

When looking at the front surface of the thread, you can see two or more thread starts symmetrically relative to each other. The number of thread starts determines the number of threads. Two thread starts are referred to as a two-start thread.

What does the thread designation TR20x8P4 mean and how can the number of threads of this type be calculated?

Example of a trapezoidal thread:

Trapezoidal thread: TR20x8P4

Diameter screw thread: 20mm

LEAD (L): 8mm

PITCH (P): 4mm

Number of turns: 8/4=2 (LEAD/PITCH) = number of turns)

TR20x8P4 = 2-start thread

Example high spiral thread

High spiral thread: DS10x12

Nominal thread diameter: 10mm

LEAD (L): 12mm

PITCH (P): 3mm

Number of turns: 12/3=4 (LEAD/PITCH) = number of turns)

DS10x12 = 4-start thread

Single trapezoidal thread

Single trapezoidal threads are often self-locking, depending on the coefficient of friction. This effect can only be attenuated with a very low coefficient of friction. The flank angle and the friction prevent the spindle nut or the threaded spindle from moving without external forces being applied. As soon as the static friction is exceeded, the parts are no longer self-locking. Multi-start trapezoidal thread drives have a “rest self-locking” feature. High helix thread drives do not have a self-locking feature.

Advantage of multiple-start threads

When using multiple-start threads, the effective supporting surface increases under the condition of a constant core diameter. Multiple-start threads are often used for high helix threads. Advantages of multi-start threads:

- Lower surface pressure means longer service life

- More precise system, due to a smaller clearance between the tooth flanks