QUALITY

Quality is one of our key differentiators in a crowded market. We have fully-equipped material labs in Europe and Asia so we can perform in-house tests in accordance with critical specifications. We are able to produce products according to international standards based on product, production and/or organisational, including ISO 9001, ISO 14001, IATF 16949, ASME, ClassNK, Norsok, KR and ABS.

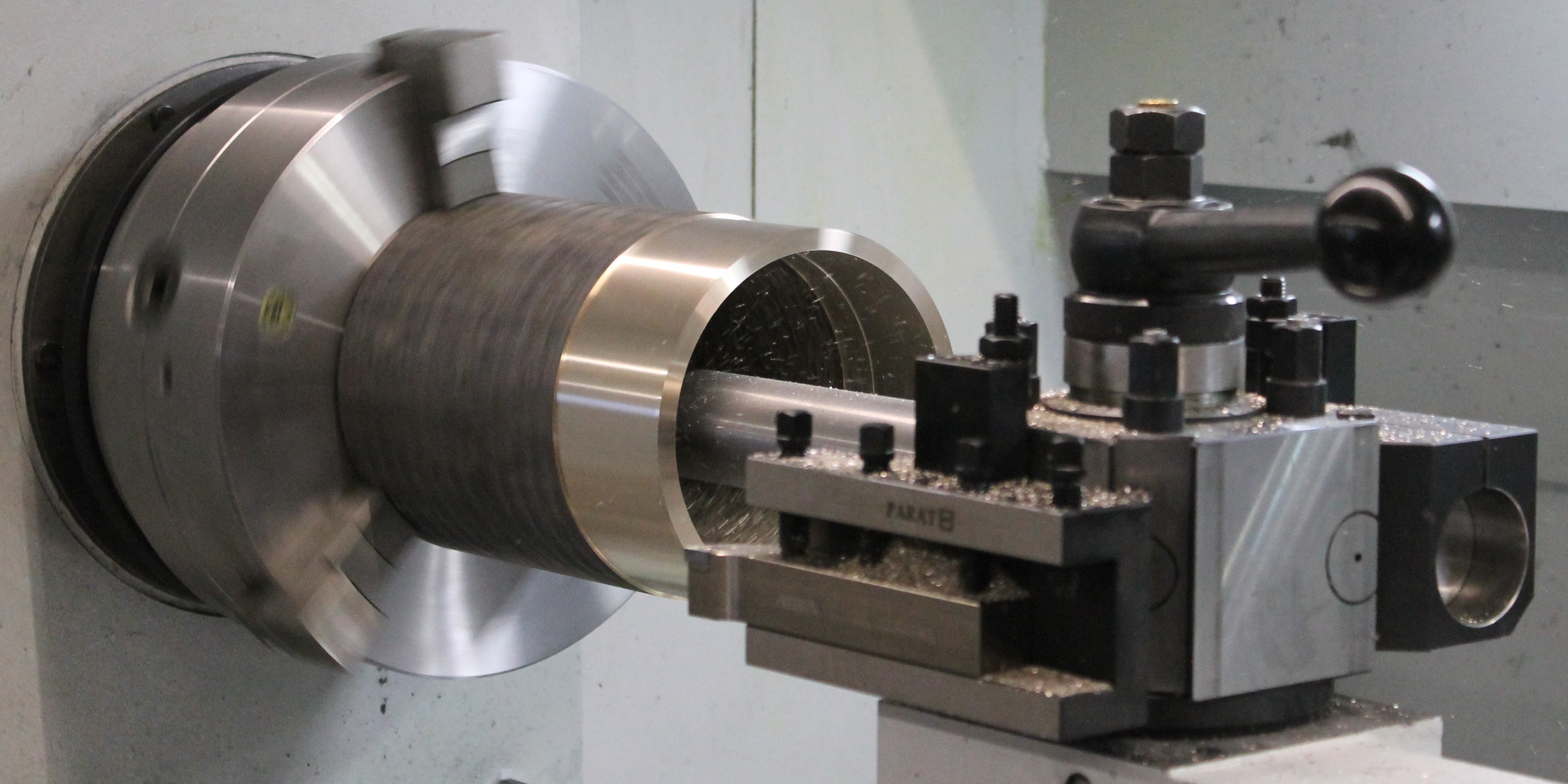

Our quality procedure is based on our many years of manufacturing experience and your specific requirements. We focus on in-house control during the production process to ensure that only approved products are shipped.

Measuring instruments

Our measuring instruments comply with the latest regulations. The measuring instruments we use in our technical centres include:

- Spectro analysers: to determine the chemical composition of metals

- Roughness tester: to measure roughness of surfaces according to DIN EN ISO 13565-1

- Hardness tester: to determine the metal hardness with Brinell hardness testing and Rockwell testing

- 3D measuring machine (CMM): to measure up to 0.005 mm with a maximum measuring range of 1.2 m

- Pull bench: to calibrate tensile strength up to 850 kN, with a clamping length of 10 m

- Classic measuring instruments: pen and ring gauges, 3-point inside micrometer, 2-point inside measuring instrument, external micrometer, altimeters, layer thickness meter, paint adhesion tester, endoscope

- XRF analyses: to determine the chemical composition of metals

- Tensile test

- Charpy impact test

- Pressure test

Highlights quality

- Fully-equipped quality and material testing labs in Europe and Asia

- Dedicated product qualities assurances procedures based on your requirements and our experience

- Quality assurance of products before shipment

- Only approved products are shipped