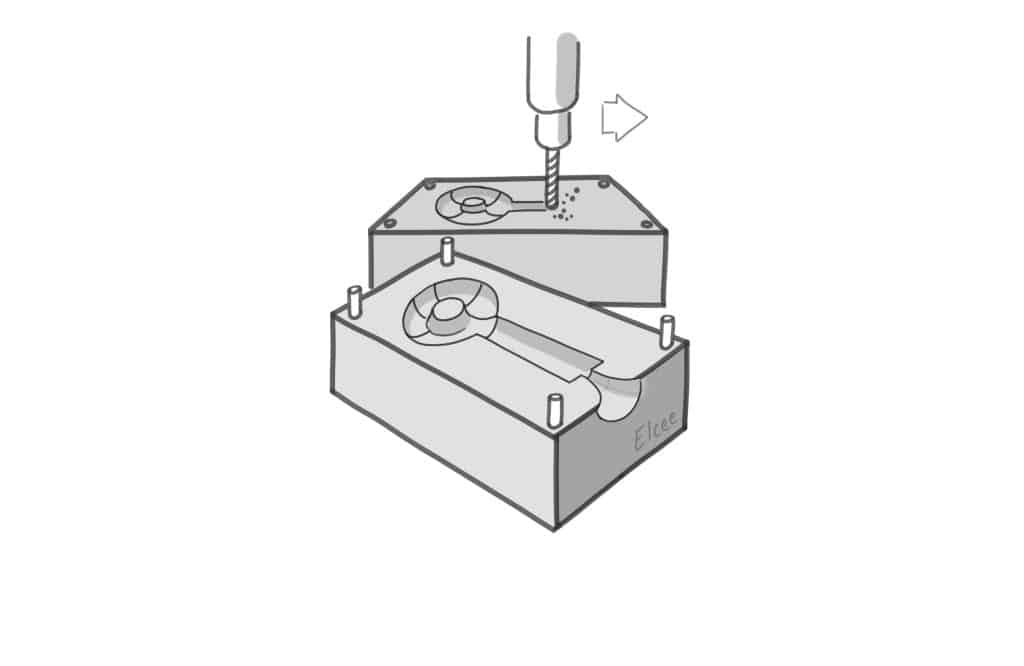

Gravity die casting (low pressure die casting)

Complex internal cavities can be produced with gravity die casting (low pressure die casting).

Complex internal cavities can be produced with gravity die casting (low pressure die casting).

Benefits

- More possibilities compared with sand casting

- Consistent dimensional accuracy

- Possibility to insert metal parts in the casting (such as bolts, pipes etc.)

- Highly suitable for finishing operations

Possible alloys

- Aluminium alloys

- Magnesium alloys

- Copper alloys

Technical specifications

- The commonly used casting tolerance table for linear dimensions is CT8 according to ISO 8062 (wall thicknesses CT9)

- Weight: 30 grams to 80 kg

- Casting surface roughness: ± Ra 6.3 μm

- Maximum dimensions: 1000 mm

- Casting wall thickness: ≥ 3 mm. Wall thickness should be distributed as evenly as possible

- The geometric tolerances that are required for the function should be specified in the drawing

- The minimum draft angle depends on the height of the wall or rib. The higher it is, the smaller the required minimum draft angle. Minimum draft angle from 1°, starting from 2° – 3°

- The position of the ejection pins must be discussed with the customer

Finishing options

- Technically anodising, but not decorative (it turns a mottled matt black)

- Blasting

- Vibra-polishing

- Primer, wet painting and powder coating