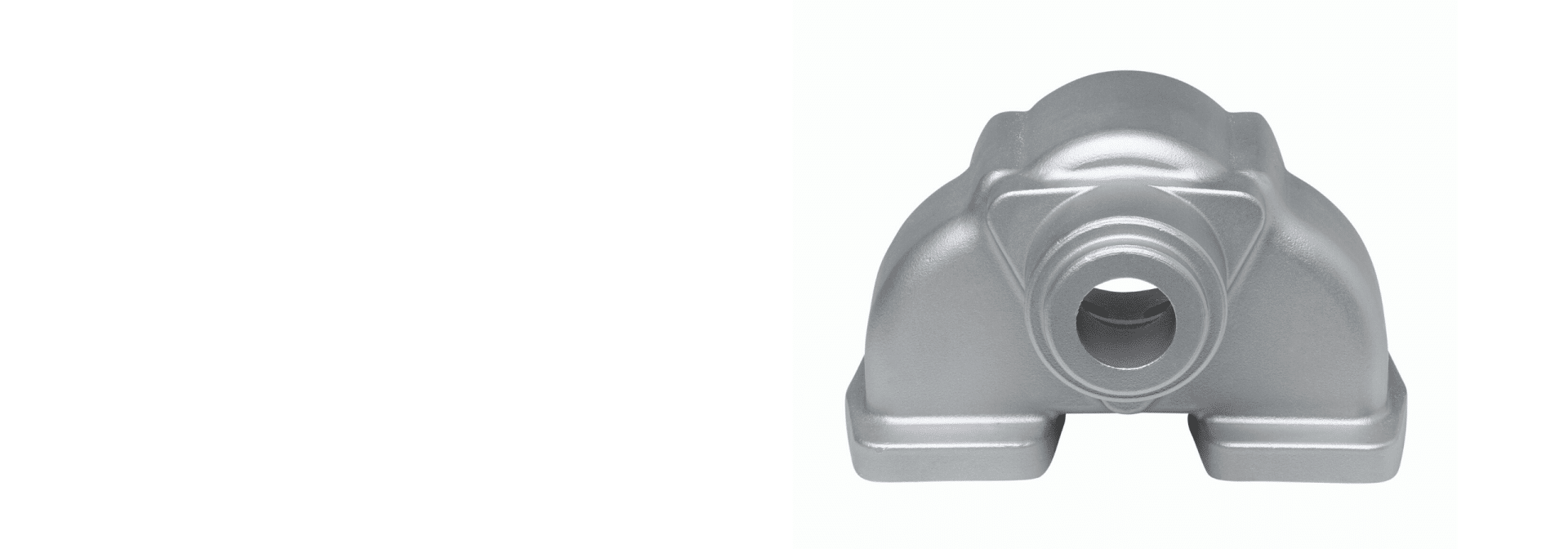

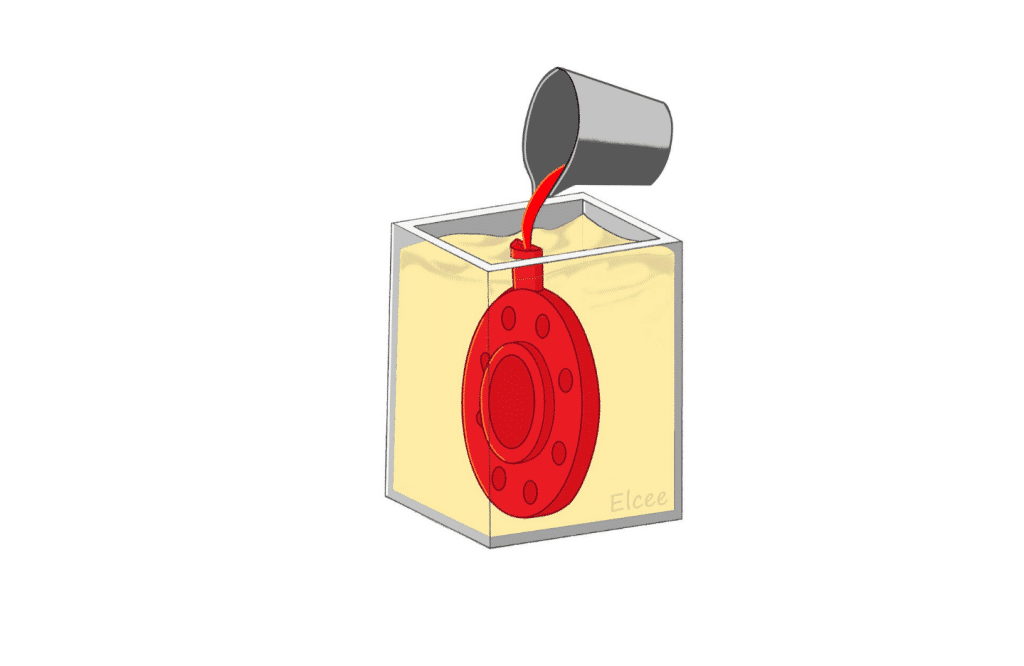

Shell moulding

Shell moulding enables the manufacturer to create complex parts with thin sections and small projections. The technique of shell moulding also imparts high dimensional accuracy and is particularly suited for castings under 75 kg. However, shell moulding can be used on almost any metal that can be sand cast.

Benefits

- Smooth surface quality

- Thin wall thickness

- Low cost moulding process

- Higher accuracy in comparison to sand casting

- Small to large series

Possible alloys

- Stainless steel and duplex grades

- Carbon steel

- Non-ferrous steel alloys e.g. aluminium and copper

Technical specifications

- The commonly used casting tolerance table for linear dimensions is CT9 according to ISO 8062 (wall thicknesses CT10)

- Weight: ± 0.2 – 75 kg

- Casting surface roughness: steel Ra 50 – 100 µm, Iron 25 – 50 µm

- Maximum dimensions: 800 mm x 800 mm x 300 mm

Design guidelines

- Avoid abrupt transitions and use radii

- Angle tolerances: ± 1°

- Casting wall thickness: ≥ 4 mm

- Use even wall thickness to minimise shrinkage

- Geometric tolerances required for the function, should be specified on the drawing

Finishing options

- Hot-dip galvanising

- Primer, wet painting and powder coating

- Blasting (sand/glass)

- KTL/e-coating

- Geocote