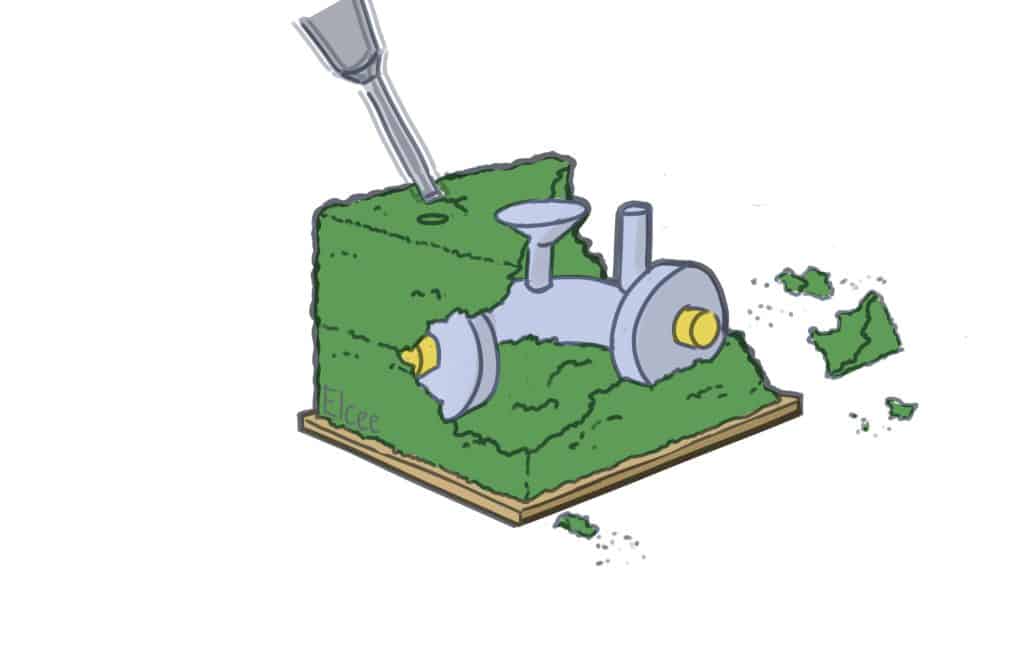

Sand casting

Sand casting can create exceptionally complex or detailed castings and can be used to cast nearly any metal alloy.

Benefits

- High production adaptability

- Small quantities are possible

- Large components can be made

Possible materials

- Ductile cast iron (also ADI – Austempered ductile iron)

- Grey cast iron

- (Stainless) steel

- Non-ferrous metal

Technical specifications

- The commonly used casting tolerance table for linear dimensions is CT10 according to ISO 8062 (wall thicknesses CT11)

- Weight: from 0.2 kg

- Maximum dimensions: 2,000 mm

- Casting wall thickness: ≥ 6-8 mm. Smaller is possible, depending on the structure

- Draft angle: min. ± 1.5°

- Geometric tolerances that are required for the function should be specified in the drawing

- As far as possible, use uniform wall thicknesses to achieve a uniform solidification of material. In case of different wall thicknesses, inclusions and cracks, and even porosity may result

Finishing options

- Electrolytic zinc plating

- Blasting

- KTL (Cataphoresis)

- Primer, wet painting and powder coating

- Hot-dip galvanising