Webinar shell moulding and sand casting

Webinar shell moulding and sand casting

Are you interested in a detailed explanation about shell moulding and sand casting? Join our webinar!

This webinar compares the casting processes of shell moulding and sand casting. The processes deviate in technical specifications, which also lead to differences in applications. Feel free to attend this webinar given by managing director ELCEE NL Marco Barendse. The webinar runs every 15 minutes at Tuesday March 16th, 2021 between the hours of 5:00 AM to 11:00 PM – Amsterdam.

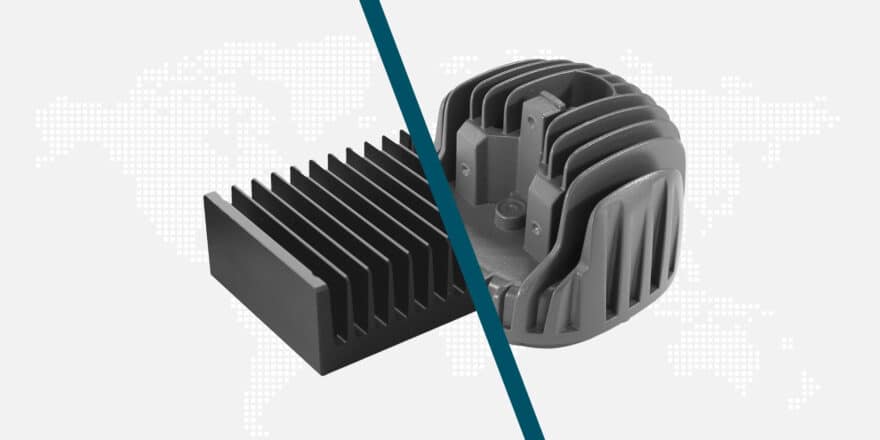

Differences between shell moulding and sand casting

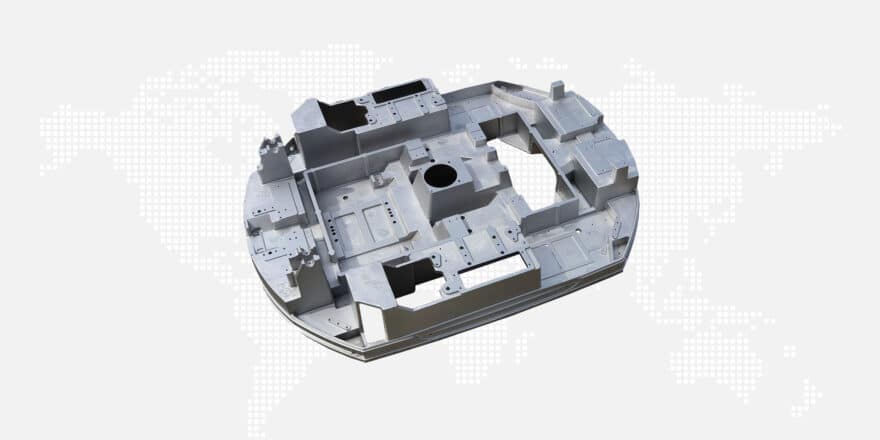

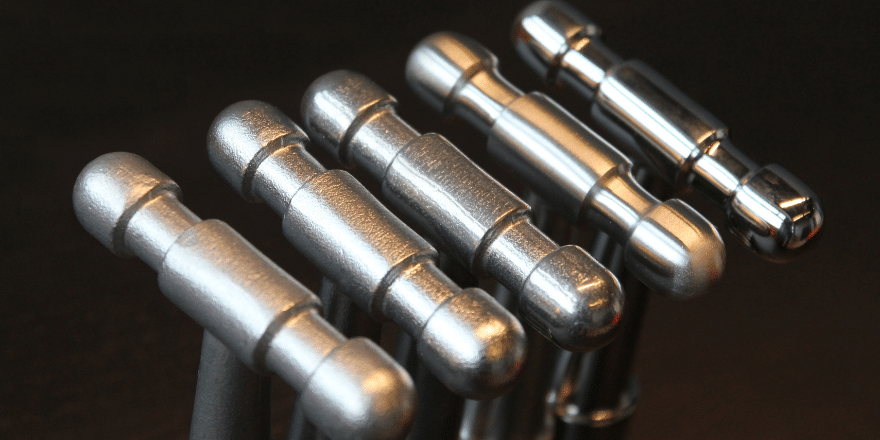

Complex parts can be made with thinner wall thicknesses and high dimensional precision using shell moulding. This is a metal casting technique that uses a mould made of a thin-walled, hardened sand shell made from a thermosetting resin, which is reinforced by another material (often fine gravel). The inside of the shell mould is extremely smooth and solid, allowing liquid metal to flow freely.

Sand casting is a widely used technique that can be done manually, automatically, or semi-automatically, depending on the quantity required.

Both techniques are possible in grey or nodular cast iron, aluminium, steel, and stainless steel are all common materials for this technique. The manufacturing procedure is straightforward. Cores may be used to create more complex shapes.

Corporate social responsibility (CSR)

The processes’ differences are contrasted. Shell moulding, for example, has a higher level of corporate social responsibility (CSR). What is the reason for this? By this technique the shells move towards the furnace where the molten metal is poured into the shell. By always pouring on the same spot, good air filters can be used to clean the polluted air easily. The difference with sand casting is that the sand boxes are strewn around the working area, which means the moulded metal must be transferred to the sand box. The sand box must be filled on site. As a result of the increased pollution in the air, the shell moulding process becomes more favourable for this specification.

Summary of key issues

The key choices, general benefits of methods, such as low casting costs and small to large series, are outlined and will be further explained in the webinar. This is particularly interesting for engineers, project managers, product managers. These applications are typically used in the offshore industry, pump and valves industry, agriculture and truck & trailer industry.

Would you like to know more?

Please do not hesitate and contact us on the 16th of March or seize the opportunity to speak to one of our managers personally. Marco Barendse is here to share his expertise and knowledge of the casting processes as he has been working 20 years for the ELCEE group.

Feel free to register for the webinar on the 16th of March and gain more insight into the production processes of shell moulding and sand casting!