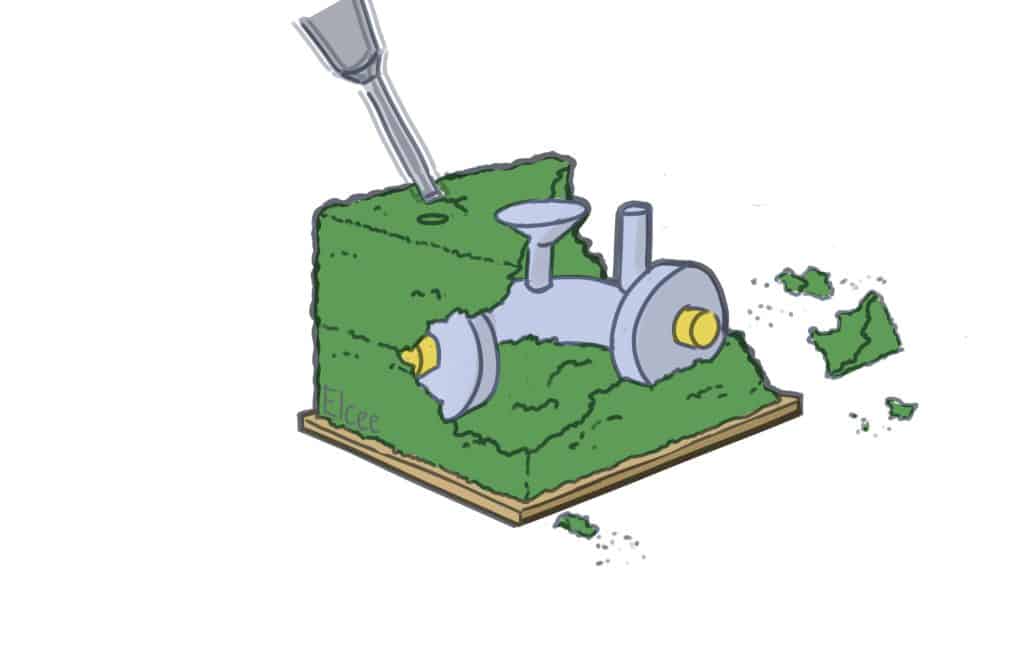

Sand casting

Sand casting can create exceptionally complex or detailed castings and can be used to cast nearly any metal alloy.

Sand casting can create exceptionally complex or detailed castings and can be used to cast nearly any metal alloy.

Benefits

- High production adaptability

- Small quantities are possible

- Large components can be made

Possible materials

- Ductile cast iron (also ADI – Austempered ductile iron)

- Grey cast iron

- (Stainless) steel

- Non-ferrous metal

Technical specifications

- The commonly used casting tolerance table for linear dimensions is CT10 according to ISO 8062 (wall thicknesses CT11)

- Weight: from 0.2 kg

- Maximum dimensions: 2,000 mm

- Casting wall thickness: ≥ 6-8 mm. Smaller is possible, depending on the structure

- Draft angle: min. ± 1.5°

- Geometric tolerances that are required for the function should be specified in the drawing

- As far as possible, use uniform wall thicknesses to achieve a uniform solidification of material. In case of different wall thicknesses, inclusions and cracks, and even porosity may result

Finishing options

- Electrolytic zinc plating

- Blasting

- KTL (Cataphoresis)

- Primer, wet painting and powder coating

- Hot-dip galvanising