ELCEE – Your Weld2cast Partner

At ELCEE, we specialize in re-engineering and we’re your trusted partner when it comes to Weld2cast. With our expertise and dedication to providing high-quality solutions, we’re here to meet all your Weld2cast needs.

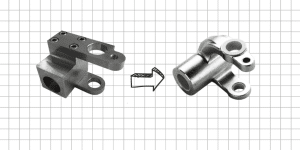

What is Weld2cast?

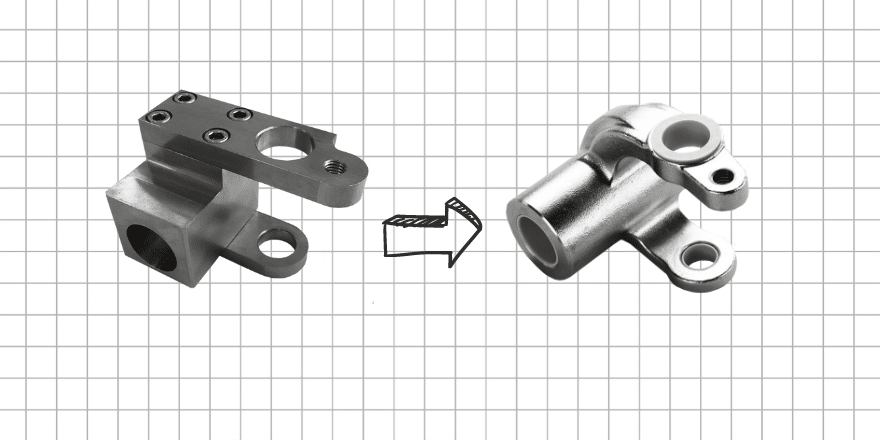

Weld2cast, also known as re-engineering or value-added engineering, is a unique process that combines the benefits of welding and casting. It involves re-engineering welded constructions to create a single, solid casting or forging. During this process, our focus is on optimizing the design, materials, and manufacturing processes to increase the value of the product while minimizing costs and improving quality.

Weld2cast offers several advantages, including improved strength, reduced weight, and enhanced performance.

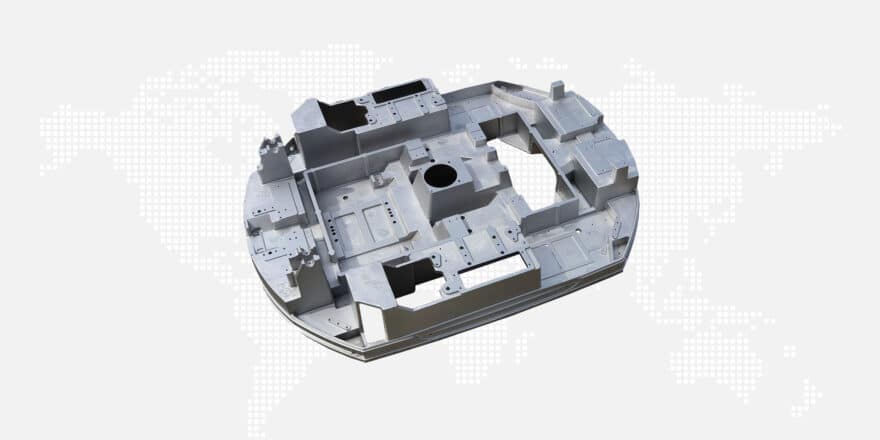

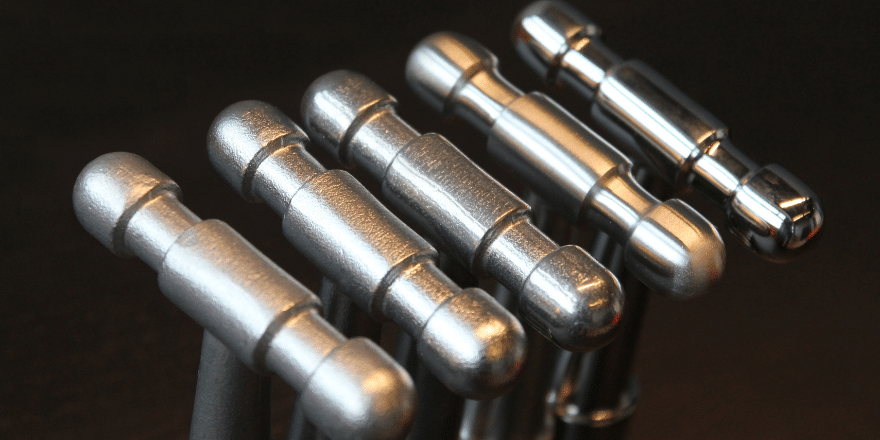

Benefits of Castings and Forgings

By using castings and forgings in product development, engineers and designers can create products that are stronger, more durable, and more reliable. This helps increase the value of the product while reducing costs and improving overall performance. Additionally, the ability to create complex shapes with castings and the strength and durability provided by forgings can improve the overall design, leading to a better customer experience and increased satisfaction.

Why Choose ELCEE as Your Weld2cast Partner?

When it comes to value-added engineering, ELCEE is the reliable partner you can count on for several reasons:

- Expertise: Our team of skilled engineers and technicians have extensive experience in the Weld2cast process. They understand the intricacies and can provide tailored solutions to meet your specific requirements.

- Quality: Quality is our top priority. Our Weld2cast components undergo rigorous testing to ensure they meet the highest standards of durability and performance.

- Customization: We understand that every project is unique. That’s why we offer customized Weld2cast solutions to suit your individual needs. Whether you need specific dimensions, materials, or finishing options, we can accommodate your preferences.

- Reliability: ELCEE has a proven track record of delivering Weld2cast solutions on time and within budget. We value our customers’ trust and strive to exceed their expectations with every project.

Capabilities for Various Materials

ELCEE specializes in re-engineering components and offers capabilities for various materials, including Iron, Ductile Iron, ADI, Stainless steel, Alloy steel, Carbon steel, Aluminium, and Brass alloys.

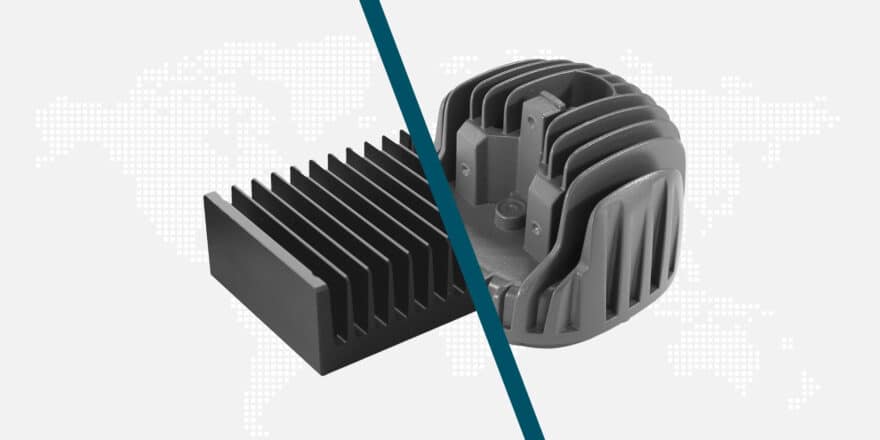

Advantages of Converting Welded Parts into Castings or Forgings

By converting a welded part into a casting or forging using Weld2cast, you can benefit from the following advantages:

- Increase product performance: enhanced strength, wear resistance, and toughness.

- Removes stress in joints and welding deformations: One-piece casting solution eliminates potential issues.

- Reduce weight: achieve lightweight solutions for improved efficiency.

- Reduce the number of components: simplify the overall design by eliminating unnecessary parts.

Contact ELCEE for Your Weld2cast Needs

Whether you need assistance with re-engineering existing components or require Weld2cast solutions for a new project, ELCEE is here to help. Contact us today to discuss your requirements and discover how we can be your trusted Weld2cast partner.