ELCEE ensures low friction for the monopile gripper

ELCEE provided all the important plain bearings in the monopile gripper

ELCEE provided all the important plain bearings in the monopile gripper in the video; sliding pads, bearing bushes and washers. We ensured low friction of the system at all pivot points. In addition, we also achieved a maintenance-free operation for many parts. Interested to find out how ELCEE can achieve low friction for the system in your product? Combined with a maintenance-free operation? Continue reading.

Why ELCEE?

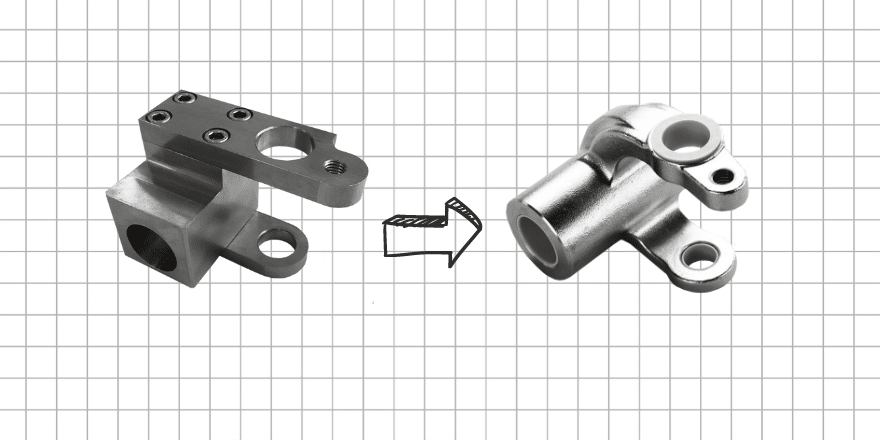

Due to the plain bearing experience of ELCEE in the offshore industry we were involved at an early stage of the design of this highly sophisticated monopile gripper. Because of our fast delivery times, technical advice and possibilities for optimizing the plain bearing parts, the customer wanted to work together.

The result: an optimized plain bearing design that ensures a large number of problem free offshore installations. By choosing our TriboTop® material, the plain bearing series were delivered perfectly within the required time frame to the highly skilled fabricator.

Please accept marketing-cookies to watch this video.

What is a monopile gripper?

Monopiles are the foundation of wind turbines. The monopile gripper is the key to lowering and positioning these monopiles safe, accurate and straight, during often challenging environmental conditions. The gripper is designed to keep the monopiles in the correct position.

This is why customers choose ELCEE plain bearings

All plain bearings in the monopile gripper are made of our TriboTop® composite material; a fibre reinforced plastic provided with solid lubricants, for a maintenance free bearing solution. TriboTop® composite bearings are seawater resistant, self-lubricant, suited for high loads and shock resistant. These plain bearings guarantee a long operation of the gripper without maintenance and with low friction.

Our extensive range of TriboTop® composite plain bearings are ideally suited for medium and high load applications. They are available in tube and plate form, but also as a complete machined product according to drawings, such as bushings, bearings, etc. TriboTop® is widely used in on- and offshore, dredging, shipping and heavy industry.

Our TriboTop® composite plain bearings offer many advantages:

- Maintenance free

- High wear resistance: good wear resistance, longer service life

- Low friction coefficient: combinations of higher loads and higher speeds are possible

- Very high load capacity: high surface pressure, which is derived from the orientation and properties of the fibre reinforcements

- Compensation of alignment errors

- Absolutely no fretting

- Good chemical resistance

- Excellent elasticity: great ability to absorb high loads and impact loads

- TriboTop® materials are non-toxic and can be used in applications for the food industry, etc.

ELCEE sliding pads in a monopile gripper. Curved sliding pads. These sliding strips ensure a smooth movement of various moving construction parts.

Curious what we can do for you?

Our engineers are ready to help you with the design of your plain bearings. We can make a calculation, make a good proposal for your design and help you make the right choices for your application. Whether it’s about replacing your plain bearings, assembly, choosing the right plain bearing material or just calculating the right plain bearings. ELCEE is ready to support you.