FROM SHEET METAL TO ALUMINIUM CASTING: THESE ARE THE ADVANTAGES

Aluminium casting techniques, particularly aluminium die casting, offer significant advantages over sheet metal for larger production volumes. In this blog, we will discuss the technical and design-related benefits of aluminium casting compared to sheet metal.

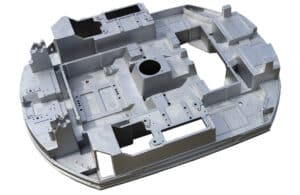

COMPLEX SHAPES, FEWER COMPONENTS

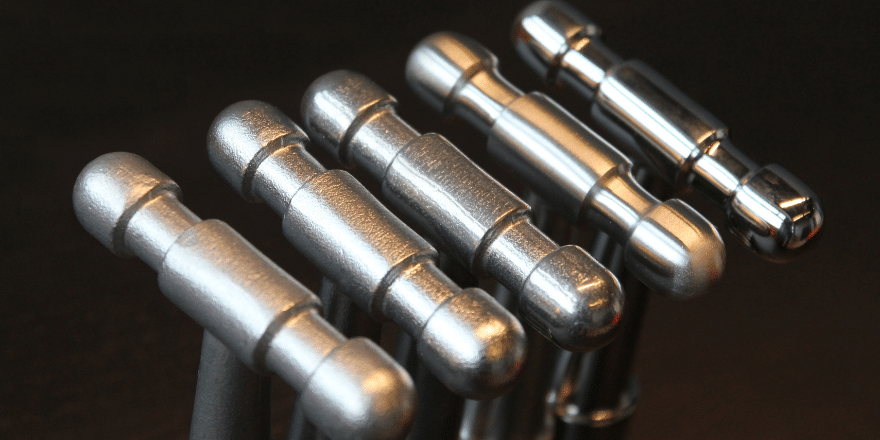

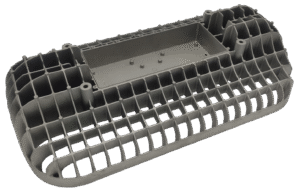

Aluminium casting provides a lot of design freedom. Integrated connection points, internal ribs, and closed cavities can easily be incorporated into one cast part. This reduces the number of individual components, saves assembly time, and decreases the likelihood of failure points. The result: an efficient production process and a reliable product.

Aluminium casting provides a lot of design freedom. Integrated connection points, internal ribs, and closed cavities can easily be incorporated into one cast part. This reduces the number of individual components, saves assembly time, and decreases the likelihood of failure points. The result: an efficient production process and a reliable product.

STRUCTURAL COST SAVINGS WITH LARGER VOLUMES

The initial investment in casting tools is higher than that for sheet metal, as a mould needs to be created first. However, in mass production, this cost is quickly recouped. In the case of sheet metal, several processes (such as cutting, bending, welding, drilling, and assembling) are often required to achieve the desired final product. With aluminium casting, many of these steps can be integrated into a single casting process. This shortens lead times, lowers production costs, and reduces the chance of errors. Furthermore, paintwork can often be directly integrated into the casting process, resulting in additional efficiency.

STRENGTH, PRECISION, AND WEIGHT REDUCTION

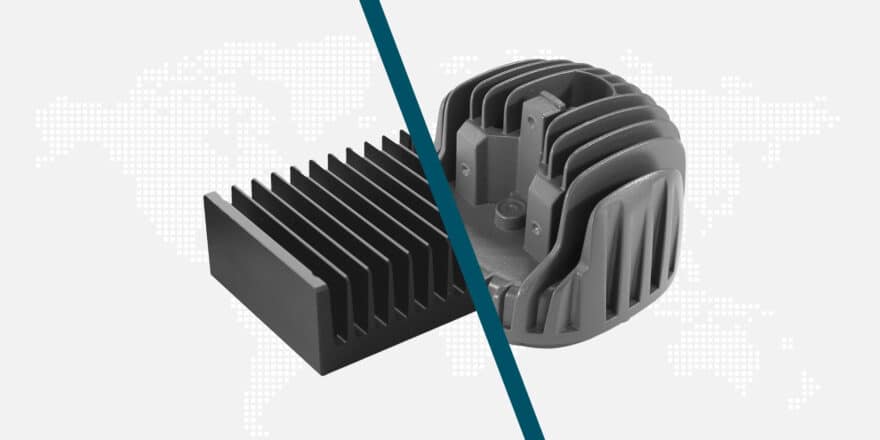

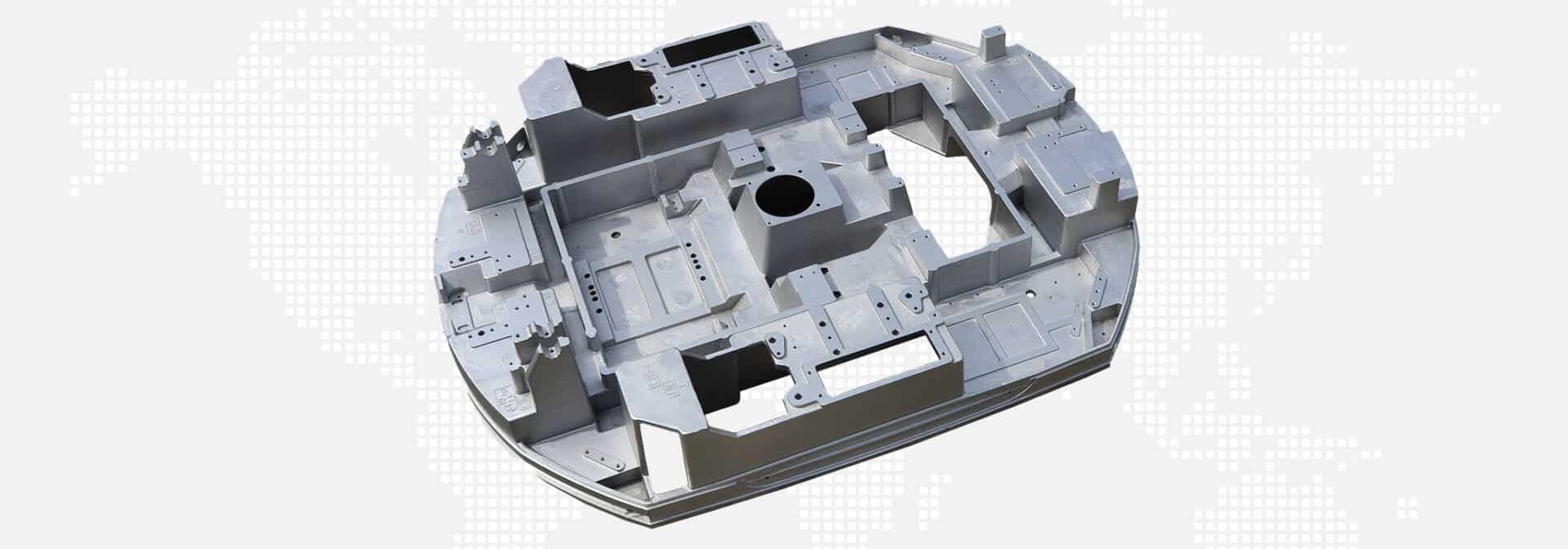

The engineers at ELCEE are involved from the design phase in optimising product performance and manufacturability. They play a key role in achieving weight reduction, improving mechanical properties, and increasing the durability of your product. Transitioning from sheet metal to aluminium casting is often a smart choice. Aluminium casting offers an excellent strength-to-weight ratio, making it particularly suitable for applications where performance and weight savings are crucial, such as in machinery, mobility, and enclosures. Due to the high dimensional accuracy of aluminium die casting, little post-processing is needed, minimising material waste. With a wide range of available alloys, you can seamlessly match the material to your technical requirements.

The engineers at ELCEE are involved from the design phase in optimising product performance and manufacturability. They play a key role in achieving weight reduction, improving mechanical properties, and increasing the durability of your product. Transitioning from sheet metal to aluminium casting is often a smart choice. Aluminium casting offers an excellent strength-to-weight ratio, making it particularly suitable for applications where performance and weight savings are crucial, such as in machinery, mobility, and enclosures. Due to the high dimensional accuracy of aluminium die casting, little post-processing is needed, minimising material waste. With a wide range of available alloys, you can seamlessly match the material to your technical requirements.

RELIABLE QUALITY, SCALABLE PRODUCTION

Unlike sheet metal, aluminium casting is particularly well-suited for reproducible, large-scale production. The process delivers consistent quality, tight tolerances, and uniform mechanical properties. This results in predictable lead times, minimal risks in the supply chain, and a stable production process. The high reproducibility in serial production contributes to consistent product quality and enhances the reliability of the end product—also in the long term.

SUSTAINABLE AND CIRCULAR

Aluminium is fully recyclable, and the casting process generates less waste compared to many other manufacturing techniques. This not only reduces environmental impact but also leads to long-term cost savings. Therefore, aluminium casting is a sustainable and future-proof choice.

ELCEE, YOUR PARTNER IN ALUMINIUM CASTING

Are you considering the transition from sheet metal to aluminium casting? Then make the right choices starting in the design phase. Our engineers will support you in optimising design, material selection, finishes, and tolerances—with attention to both technical and functional objectives.

Get in touch

Schedule a technical consultation with one of our specialists and discover what’s possible for your application.