ALUMINIUM A SUSTAINABLE CHOICE FOR CASTING

With the increasing focus on a circular economy and tightening environmental regulations, aluminium metal is establishing itself as a future-proof material. The properties of aluminium align perfectly with the principles of a circular economy, where materials are kept in circulation for as long as possible. Companies that are investing in aluminium casting now are preparing for a future where sustainability and efficient material use are most important.

In this blog, we highlight the advantages of aluminium, both from a recycling and environmental perspective. As a specialist in aluminium, we aim to demonstrate why this metal is an excellent choice for the production of aluminium components and machine parts.

1. ALUMINIUM IS FULLY RECYCLABLE

One of the greatest advantages of aluminium is that it is 100% recyclable without any loss of quality. This means it can be reused infinitely, making it highly suitable for metal casting and other manufacturing processes. The recycling process for aluminium requires significantly less energy than the production of new aluminium, saving raw materials and reducing CO2 emissions. Recycled aluminium uses up to 95% less energy compared to new material production, making it one of the most energy-efficient choices.

2. LOW CO2 EMISSIONS IN ALUMINIUM COMPONENT PRODUCTION

The production of aluminium components has a relatively low CO2 emission per kilogram. Thanks to innovations in the aluminium industry, the carbon footprint has significantly reduced in recent years. This positions aluminium as a more sustainable alternative to other materials, which require much more energy during the production process.

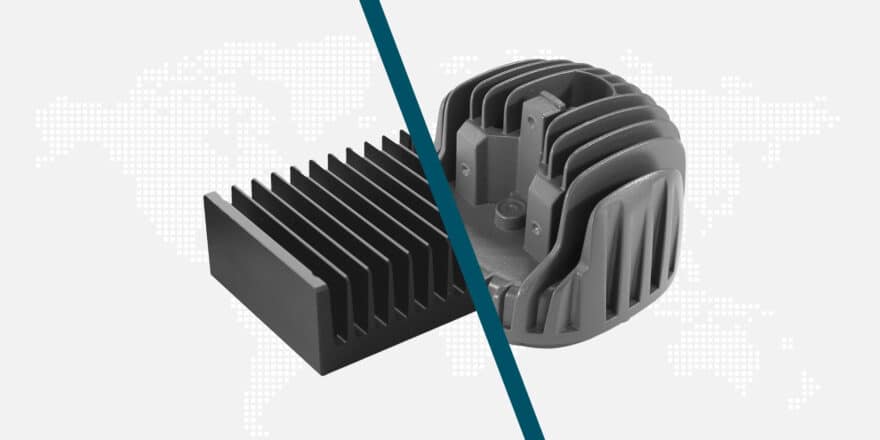

3. LIGHTWEIGHT

Aluminium is not only sustainable due to its recyclability but also because of its lightweight nature. This provides significant advantages. The use of aluminium in, for example, engine components and vehicles leads to lower fuel consumption and a reduced ecological impact of transport. Lighter parts can significantly decrease energy consumption, contributing to the sustainability of the industry.

4. LONG DURABILITY

Aluminium has a natural resistance to corrosion due to the formation of a protective oxide film. This makes the material ideal for producing aluminium parts that need to withstand harsh conditions. The long lifespan of aluminium means replacements are needed less frequently, which contributes to a lower consumption of raw materials and less waste.

5. GLOBALLY AVAILABLE RAW MATERIAL

Unlike other metals such as rare earth metals, aluminium is extracted from bauxite, which is relatively abundant worldwide. By using locally produced aluminium, transport distances and associated CO2 emissions are significantly reduced. This contributes to a smaller ecological footprint for the final product. Moreover, this availability offers a strategic advantage since production is less sensitive to price fluctuations of scarce materials.

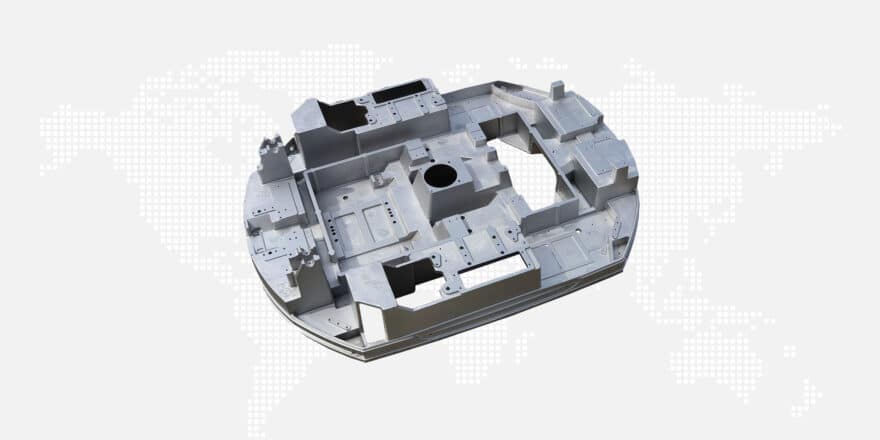

6. APPLICATIONS IN DIVERSE SECTORS

The versatility of aluminium makes it suitable for a wide range of industrial applications. From the automotive industry to aerospace and construction, aluminium is used in a broad spectrum of products. In the production of machine parts, aluminium is ideal for applications where both lightweight and durability are required. From engine components to facade systems, and from furniture to solar panels, companies across various sectors can benefit from the sustainable advantages of aluminium.

By combining these benefits with advanced techniques such as aluminium injection moulding, companies can create products that are not only technically advanced but also contribute to a more sustainable future. Therefore, choosing aluminium as a material is a strategic step for both environmental impact and long-term cost savings.

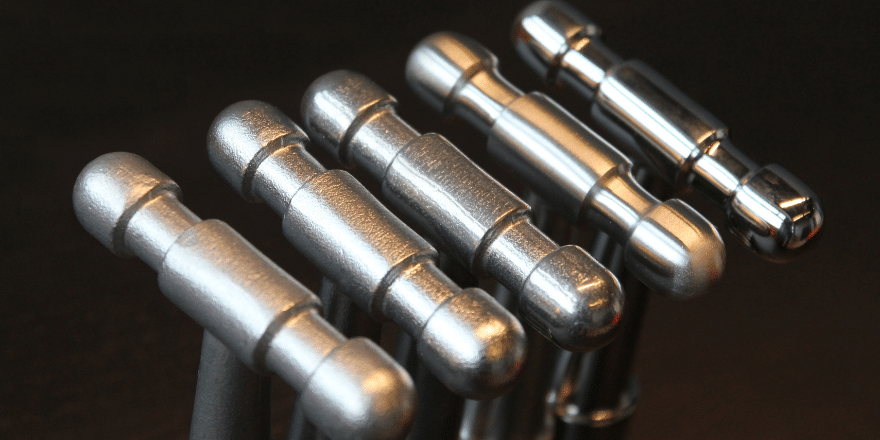

7. INNOVATIVE CASTING PROCESSES

The aluminium industry continues to innovate in casting processes, leading to even more efficient and sustainable manufacturing methods. Techniques such as aluminium injection moulding allow for the production of complex shapes with minimal material waste. This results in less waste and more efficient use of raw materials. Furthermore, these advanced techniques can lead to lighter and stronger components, further enhancing the overall sustainability of the final product.

ALUMINIUM METAL CASTING

By choosing aluminium for your metal casting processes, you not only make an environmentally conscious choice but also invest in the long-term sustainability and efficiency of your products and processes. Contact us to discuss the possibilities for your industrial components and assemblies.