ELCEE expands its product range

We recently acquired two leading companies in the field of casting and forging, Prins Metallurgical Products B.V. and ChinaWorks B.V.. These acquisitions enable us to expand our product range. We now offer you a wider and more diverse range of products and services, as well as more flexibility and efficiency for your projects.

What does this mean for you?

With the addition of Prins and ChinaWorks, we are able to provide you with:

- A complete range of casting and forging products from different regions, including East-Europe, Turkey, India and China.

- Products from small to big size, light to heavy weight in several materials, such as cast iron, stainless steel and non-ferro materials.

- Assembly possibilities close to the production region as well as in The Netherlands.

- Added solutions in cast and ductile iron and aluminium.

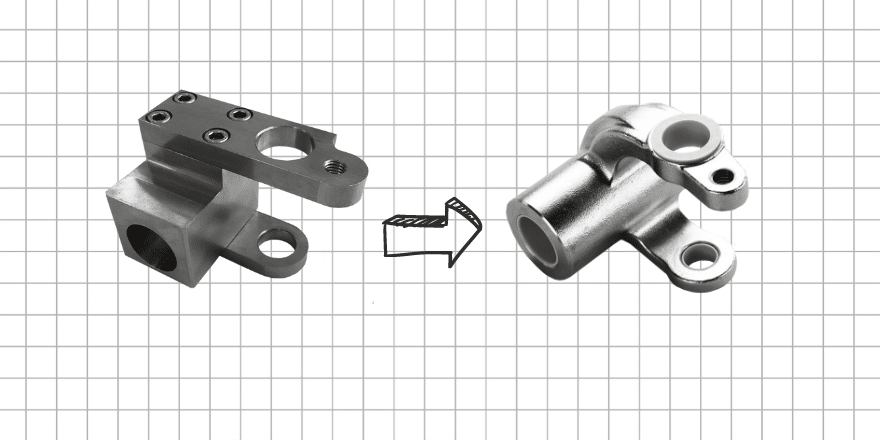

- Ability to convert bigger welding constructions into castings and forgings, with our engineering support solution.

Who is Prins?

Prins is a specialist in high-quality casting and forging products for various industries in Europe. They have more than 85 years of experience and deliver their products from their head office and logistics centre in Amersfoort. They work with carefully selected production partners in China and India.

Prins is a specialist in high-quality casting and forging products for various industries in Europe. They have more than 85 years of experience and deliver their products from their head office and logistics centre in Amersfoort. They work with carefully selected production partners in China and India.

Some of the technologies that Prins uses are:

- Lost wax casting: a technique for producing complex shapes with high accuracy and surface quality.

- Sand casting: a technique for producing large and heavy parts with various materials.

- Other casting technologies: such as ceramic casting, aluminium alloys casting, etc.

By joining forces with Prins, ELCEE can supply castings from a couple of grammes up to 150 tons, from cast iron to super duplex. We serve markets such as machine building, offshore, railway, agriculture, etc.

Who is ChinaWorks?

ChinaWorks is a specialist in the production of metal and plastic end products, semi-finished parts and components. They have a skilled workforce in China that works with state-of-the-art machines. They offer various techniques such as:

ChinaWorks is a specialist in the production of metal and plastic end products, semi-finished parts and components. They have a skilled workforce in China that works with state-of-the-art machines. They offer various techniques such as:

- High and low-pressure die casting: a technique for producing aluminum parts with high dimensional accuracy and surface finish.

- Sand casting: a technique for producing metal parts with complex shapes or large sizes.

- Extrusion: a technique for producing metal or plastic parts with a uniform cross-section.

- Plastic injection molding: a technique for producing plastic parts with high precision and low cost.

- CNC machining: a technique for producing metal or plastic parts with high accuracy and quality by using computer-controlled machines.

- Prototyping: a technique for producing small quantities of parts for testing or validation purposes.

Because ChinaWorks is part of the ELCEE group, our capabilities have broadened and ELCEE can produce parts from various materials such as aluminium, steel, iron, brass, copper, zinc, etc. We serve markets such as medical equipment, lighting, furniture, electronics, etc.

How can you benefit from our expanded product range and services?

We believe that these acquisitions will enhance our value proposition and provide you with more options and flexibility for your projects. We are committed to delivering high-quality products and services at competitive prices.

If you are interested in learning more about our expanded product range and services, please contact us or your contact person from one of the companies that belong to the ELCEE group. We would love to hear from you and discuss how we can help you with your next project.

Summary of techniques

To give you an overview of all the techniques that ELCEE has after the joining forces with Prins and ChinaWorks, here is a summary table:

Technique |

Description |

Materials |

Applications |

| Investment casting (Silica sol process) | Producing complex shapes with high accuracy and surface quality | Steel, stainless steel, non-ferro alloys | Food industry, general mechanical engineering |

| Fast dry silica sol casting | Production of larger parts with good surface quality and high forming freedom | Steel alloys | Trailer parts, agricultural industry |

| Lost wax casting (water glass process) | Production of larger parts with good surface quality and high forming freedom | Steel alloys | Trailer parts, agricultural industry |

| High-pressure die casting | Production of non ferrous parts with high dimensional accuracy and surface finish | Aluminium, zinc alloys | Electronics, lighting, furniture |

| Low-pressure die casting | Producing non ferrous parts of larger dimensions and limited complexity | Aluminium alloys | Automotive, offshore |

| Shell moulding | Production of parts with good dimensional accuracy and surface finish | Nodular cast iron , grey cast iron, (stainless) steel | Pump and valve industry, agricultural industry |

| Sand casting | Production of castings with limited complexity in both smaller and larger sizes | Nodular cast iron (also ADI grades), grey cast iron, (stainless) steel, non-ferrous metal | Pomp en afsluiter industrie, agrarische industrie |

| Extrusion | Production of profiles in aluminium or metal | Aluminium alloys, (stainless) steel and plastics | Mechanical engineering, facade construction |

| Plastic injection molding | Producing plastic parts with high precision and low cost | Plastics | Various industries |

| CNC machining | Producing metal or plastic parts with high accuracy and quality by using computer-controlled machines | Steel, stainless steel, aluminium, brass, copper, plastics | Various industries |

| Sintering | Compressing and heating metal powder into precise shapes | (Stainless) steel and bronze | Various industries, fine mechanics |

| Closed die forging | Using two or more dies to completely or partially surround a heated metal billet and shape it by applying pressure | Steel, stainless steel, aluminium | Agricultural industry, Transport |

| Open die forging | Using two dies that do not enclose the workpiece and shape it by hammering or pressing | Steel, stainless steel, aluminium | Axles, rings for heavier industry |

| Welding constructions | Assembling sheet metal parts and/or profiles by heat transfer | Steel, stainless steel, aluminium | Various industries |

Complete product range

In addition to our casting and forging services, we also sell engineered bearings, standard bearings from igus (only Netherlands), lifting and lashing products from Crosby (only Netherlands), and assemblies. Our engineered bearings are custom-made to meet the specific requirements of our customers in terms of size, shape, material, performance, and application. Standard bearings from igus are self-lubricating, maintenance-free, corrosion-resistant, and suitable for various industries. Lifting and lashing products from Crosby are high-quality and reliable solutions for rigging, hoisting, towing, and securing loads. And our assemblies are fabricated from our castings and forgings or other components according to our customers’ specifications.

We hope this summary helps you to get a better understanding of our expanded product range and services