Plain bearing brochure: Which plain bearing is optimal in your situation?

Plain bearing brochure: Which plain bearing is optimal in your situation?

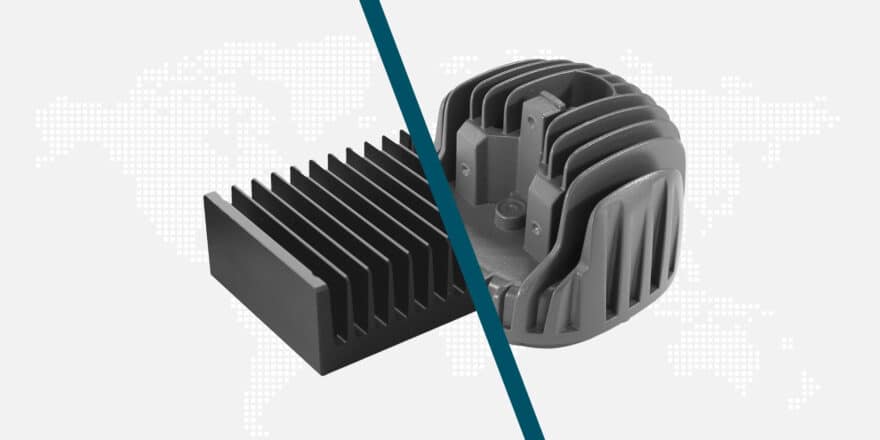

In many situations it is possible to convert a lubricated bearing to a self-lubricating bronze or plastic one, which leads to a maintenance-free plain bearing solution. A major advantage. Less maintenance, of course, means lower maintenance costs and less downtime. But is a plain bearing suitable for your application? And if so, which one is the right choice? The information in our new brochure will help you find the answers to these questions.

“Turn your (plain) bearing application into a maintenance-free solution.”

MAINTENANCE-FREE PLAIN BEARING SOLUTION

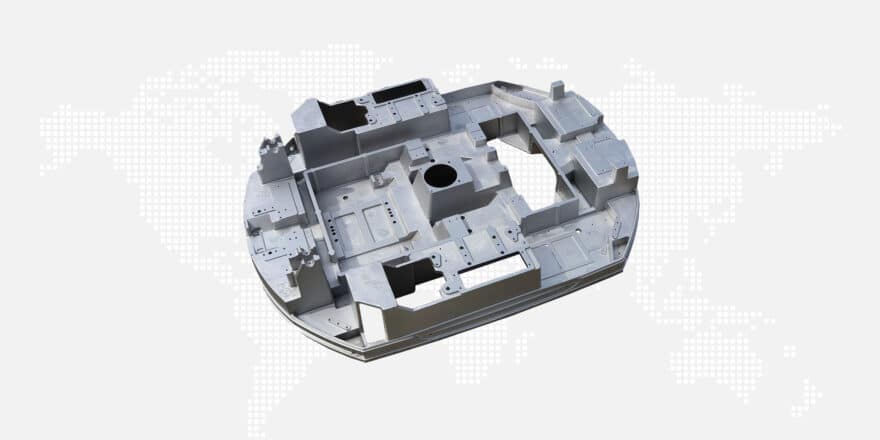

Transforming your (plain) bearing application into a maintenance-free bearing solution is the strength of ELCEE. With over 35 years of experience, ELCEE assists you with expert advice in the engineering, calculation and manufacturing of a solution that is specifically tailored to your needs. Technical support, quality control and supply chain management are standard services for all our products. Your specifications, in your project, are the focus of close cooperation.

COMPREHENSIVE RANGE OF PLAIN BEARINGS

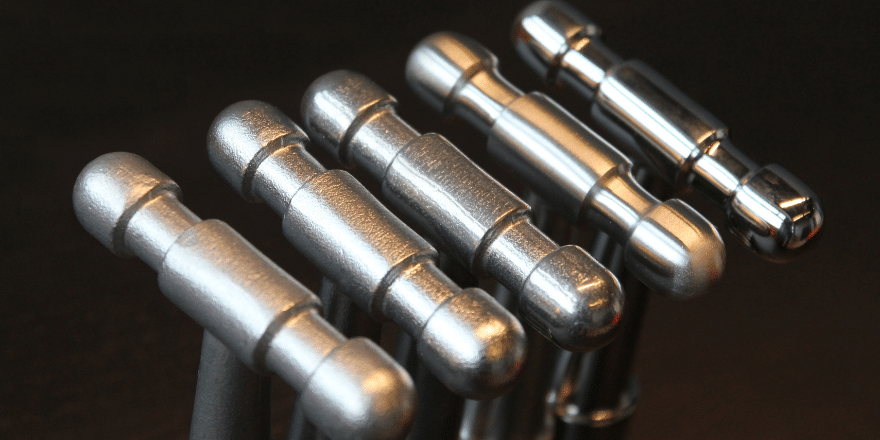

ELCEE has the most complete range of polymer bearings, composite bearings, bronze bearings, spherical bearings and high alloy steel bearings. Knowledge and experience result in ELCEE brands: Tribo Top®, Tribo Bronze®, Tribo Oiled®, Tribo Ball®, and Tribo Steel® plain bearings. Besides engineered bearings, ELCEE is also the official distributor and knowledge partner for igus® and Wärtsilä® seals & plain bearings in the Benelux. The brochure offers an overview of various plain bearing materials and all specific properties.

TECHNICAL INFORMATION ON PLAIN BEARINGS

In addition, we present the basic technical calculations, which underlie each plain bearing. The first step in selecting and choosing the right plain bearing for your application is to determine the plain bearing load (surface pressure). This is a ratio of the load to the projected surface area and is expressed as surface pressure (P) in MPa (equivalent to N/mm²). In addition to the normal bearing load, the surface speed between the two sliding surfaces is an important parameter. Calculate all movements back to a value of metres per second. The product of the surface pressure (P) and the speed (V) gives the PV-value of the application. This is an indication of the heat build-up due to friction in the bearing and is therefore an important factor when selecting a suitable bearing material. Once the PV value has been determined, there are a number of suitable materials for the plain bearing. Which material you finally choose depends on other environmental factors and your preference.

This brochure is a must-have for anyone who wants to find out quickly whether a plain bearing is the right choice for their situation.