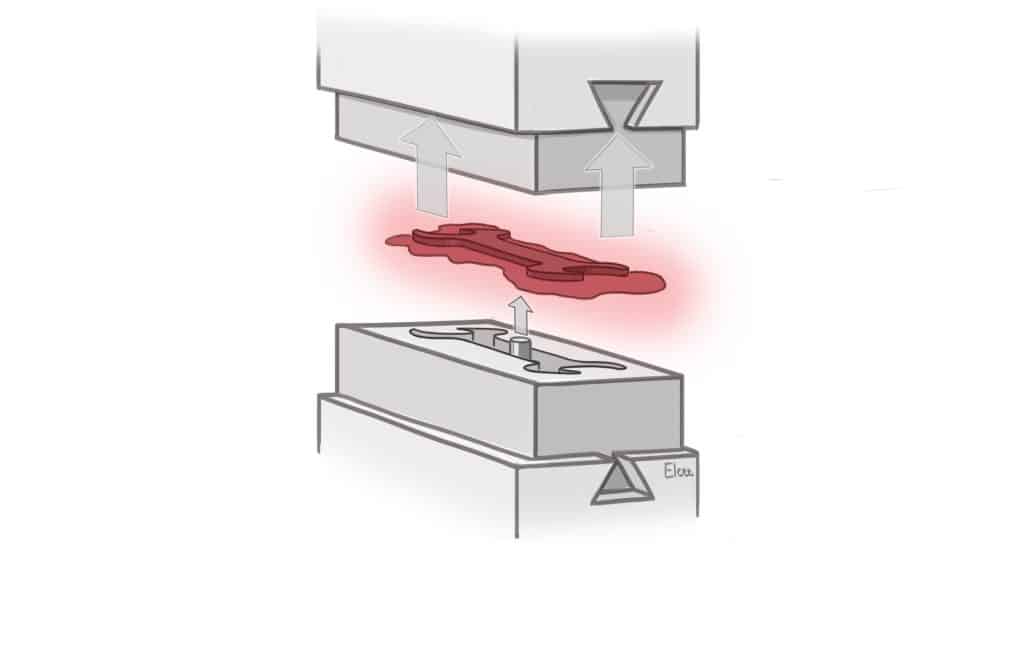

Closed die forging

Closed die forging can produce homogeneous products, with excellent mechanical characteristics.

Closed die forging can produce homogeneous products, with excellent mechanical characteristics.

Benefits

- Good repeatability

- Highly homogeneous material with mechanical properties

- High production speed

- Economical process compared with welding assemblies

Possible alloys

- Steel, alloy steel, tool steel and stainless steel

- Aluminium, bronze and copper alloys

Technical specifications

- The tolerances of steel forgings are as per EN 10243-1, and the following criteria are decisive:

- Forge weight

- Shape of the tool division

- Category of the steel (high or low alloy)

- Form complexity factor, which depends on the factor between the weight of the component and the envelope weight

- Weight: Approx. 200 grams – 120 kg, while shaft products can weigh up to 200 kg

- Maximum dimensions: length 1,200 mm

- Forging wall thickness: ≥ 4 mm

- The geometric tolerances that are required for the function should be specified in the drawing

- The most important tolerances apply to:

- Length, width, height and thickness dimensions

- Finishing of the forging edge

- An adequate draft angle should be provided; a good guideline is at least 3° for aluminium and 5° to 7° for steel

- Use large radii to avoid quick tooling wear or cracks in forgings

- Ribs should be low and wide

- The various cross-sections must be balanced to prevent extreme variations in the flow of the metal

- The tooling division must run through the centre of the forging and not along one side. The forging needs to be detachable from this division

Finishing options

- Electrolytic zinc plating

- Hot-dip galvanising

- Vibra-polishing

- Blasting

- Primer, wet painting and powder coating