Webinar technical specifications hot forging

Would you like to know more about the technical specifications concerning hot forging?

In this webinar we explain technical specifications of several closed die product examples during the hot forging process. Choice of equipment, shape complexity, materials, tolerances and cost drivers. Are you looking for more technical information to optimize your forgings? Then don’t miss out and attend this webinar given by Frank Nijhof. The webinar runs every 15 minutes at Tuesday March 30th, 2021 between the hours of 5:00 AM to 11:00 PM – Amsterdam.

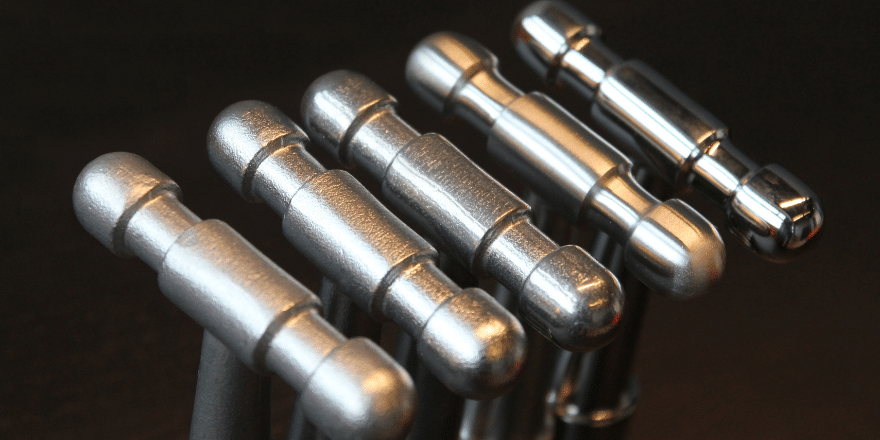

What is closed die forging?

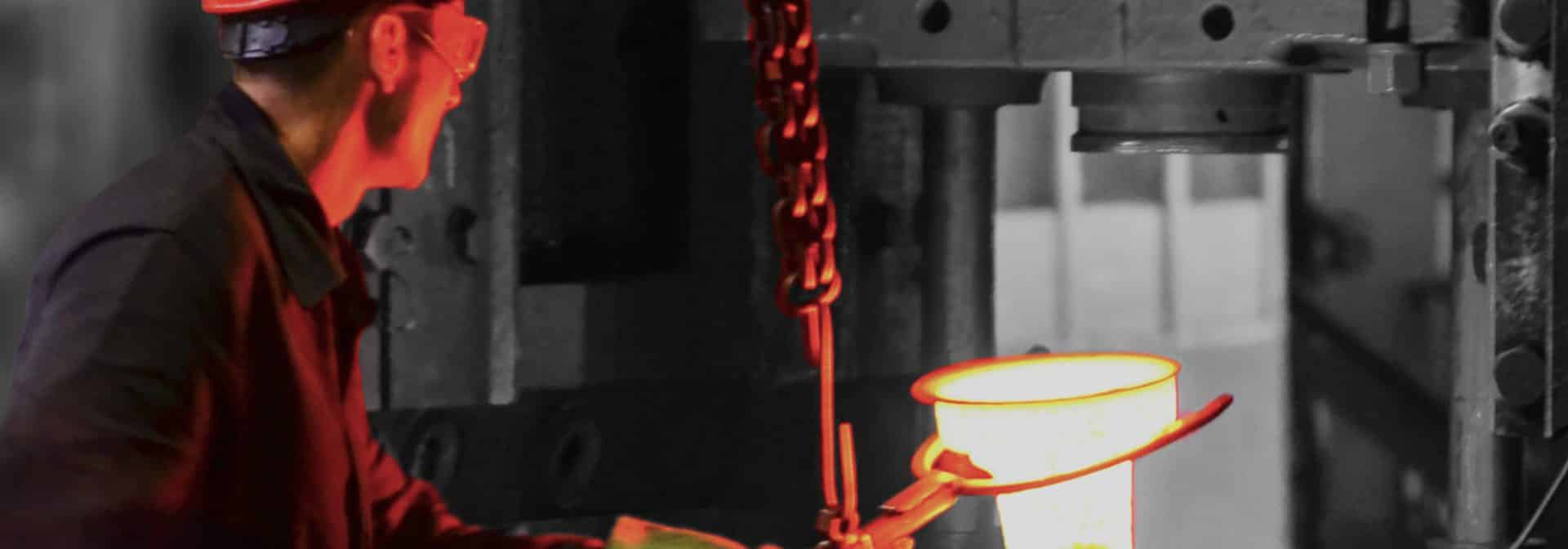

Forging is a manufacturing process that involves the shaping of metal using localized compressive forces. Closed die forging produces homogeneous products, with excellent mechanical characteristics. When the metal reaches the desired heat, it is placed in the die.

What is Hot forging?

When an initially simple shape of material is plastically deformed above the recrystallization temperature between two tools, resulting in the desired shape.

The desired shape of the forging is incorporated as a negative image in the die. The raw material is pressed into the desired shape by exerting pressure on the die. Closed die forging can be used for medium to large series. Forging weights range from 200 grams to 120 kilograms. The minimum production quantity depends on the product size, but usually starts at 1,000 pieces.

Would you like to know more about the process of the closed die product example? Please do not hesitate and contact us on the 30th of March or seize the opportunity to speak to one of our managers personally.

Processing principles

In this webinar we focus on the technical characteristics regarding the choice of equipment. There are four main classes of machines used in the forging industry. The drop hammer, the screw press, the crank press and the hydraulic press. These classes can be divided in two basic types:

- Work/force restricted

- Stroke restricted

Choice of equipment

When reviewing the costs of the forging, we can break them down in average costs. For example, the material of the workpiece is 50% responsible for the costs and shows how important this part is. For the choice of equipment, we took a product example to do the calculations for which includes energy capacity formula.

The technical specifications regarding your material are divided in classifications of the “Load factor” and the “Die life factor”. To calculate the energy capacity, you need calculations of the projected area including flash land, material load factor and the shape load factor. During the webinar we will show you the calculations of the formulas.

Register now for the interesting webinar on March 30th and learn more about the calculations when choosing your equipment.

Reachable tolerances

Production tolerances are determined by:

- Shape complexity

- Forgeability of the material

The shape complexity is defined by your mass of forging and your mass of enveloping shape. We will further explain the technical specifications of the production tolerances by calculating the expected tolerances on the length and the thickness of the product. These calculations can provide you with? answers for your material group, for example your M1 group consists of steel with carbon content not more than 0.65% and total of specified alloying elements (Mn, Ni, Cr, Mo, V, W) not more than 5% by mass.

This webinar is particularly interesting for engineers, project managers and product managers who like to know more about the shape complexity and forgeability of the material.

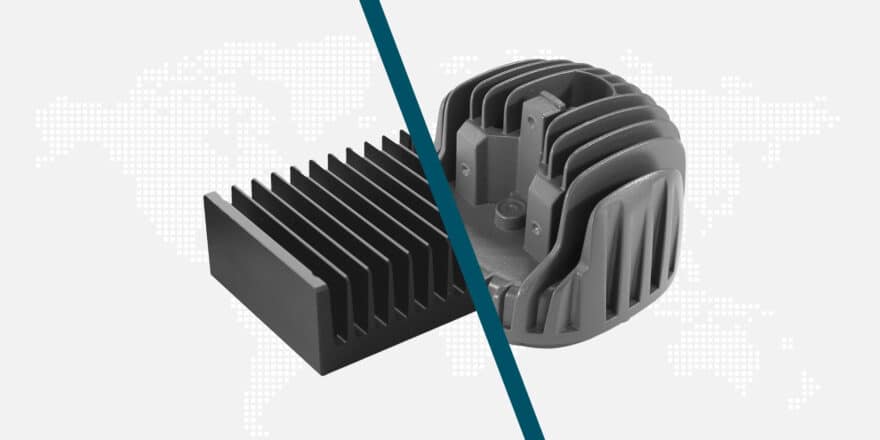

ELCEE forgings can also be designed in relatively complex shapes to reduce weight and can be optimised for mass production. We also offer several finishing options. Read more about CNC machining.

Feel free to register for the webinar on the 30th of March and enjoy listening to Frank Nijhof who has over 30 years of experience in product development, production and technology and is here to share his expertise and knowledge on the technical specifications of hot forging.